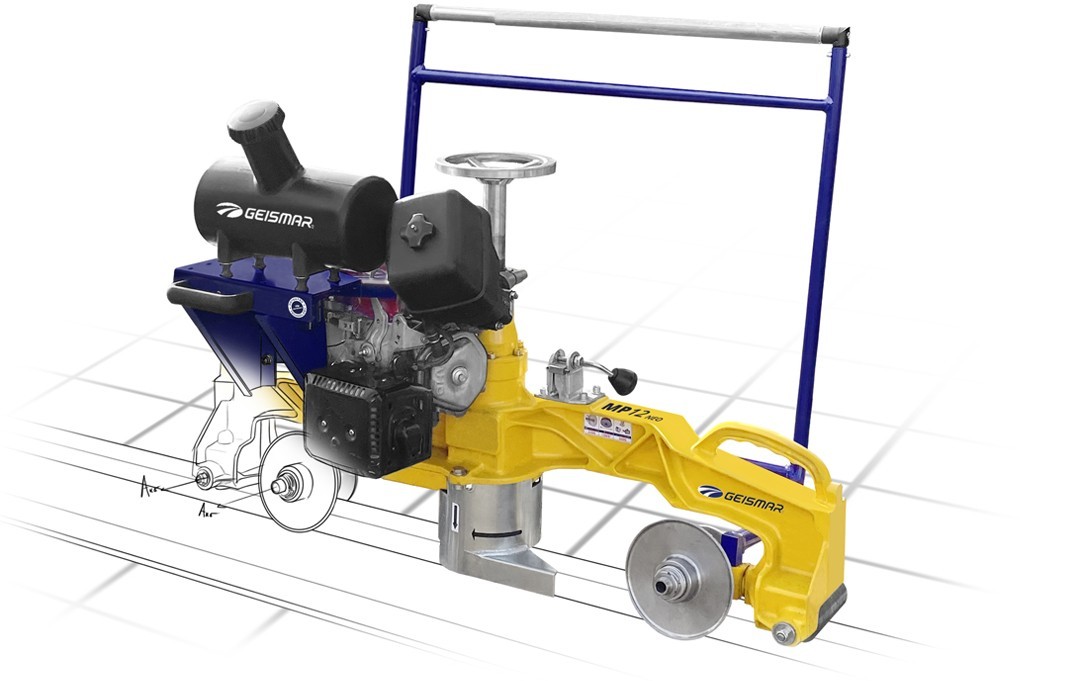

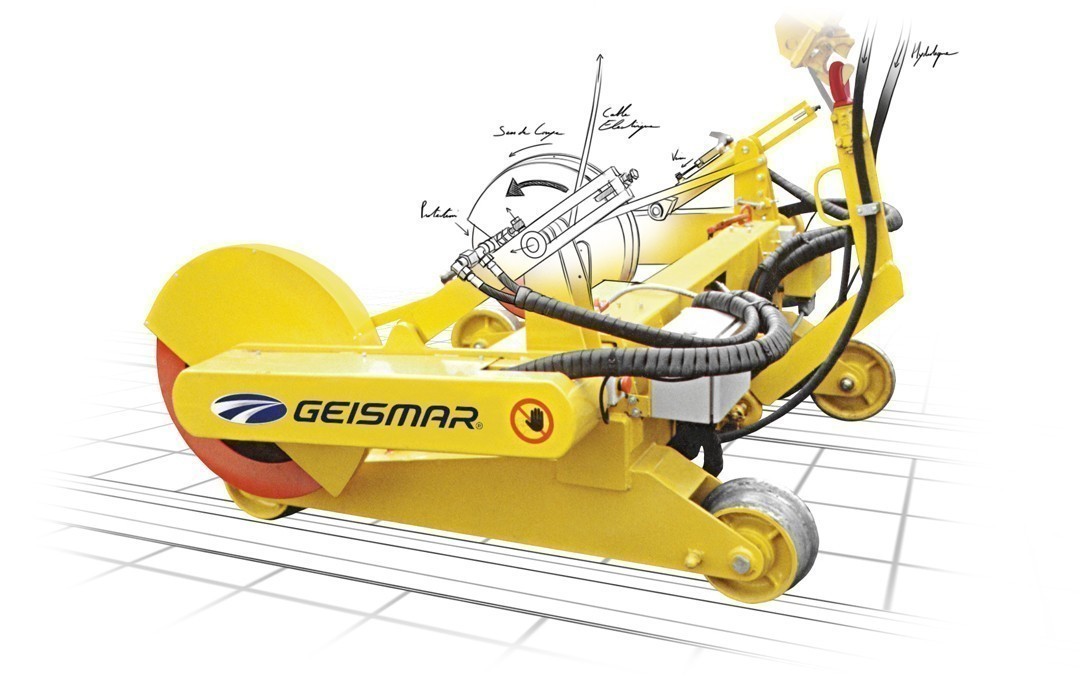

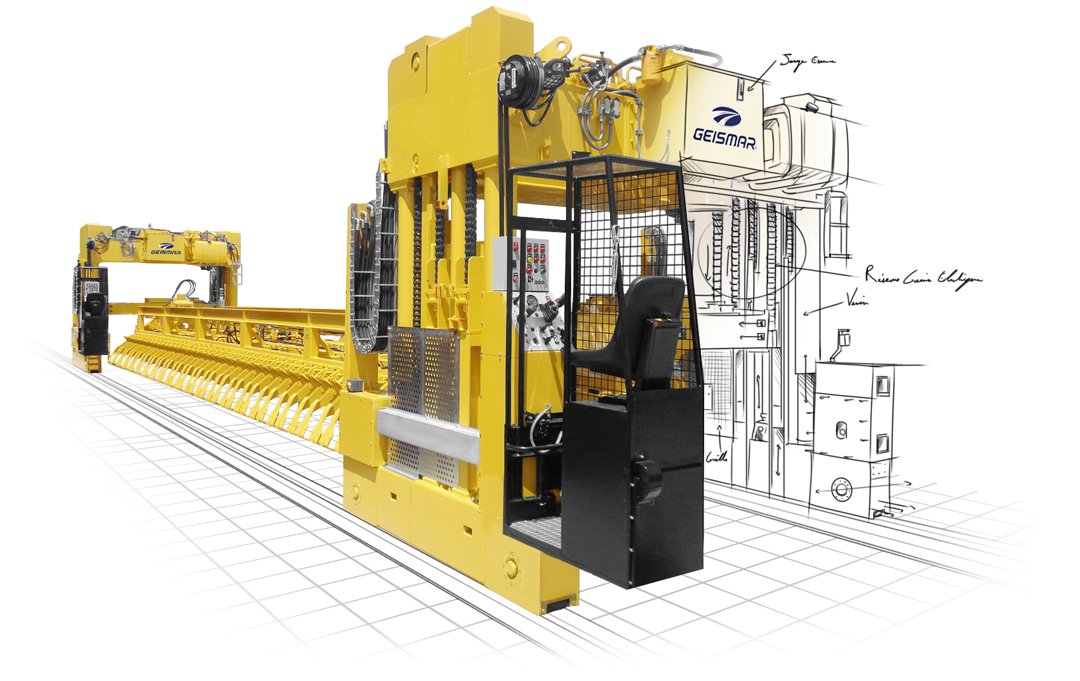

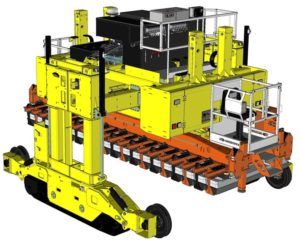

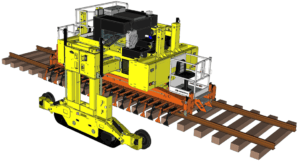

ECTR | New generation of gantry for the pulling of LWR, the handling of track panels, concrete slabs or sleepers

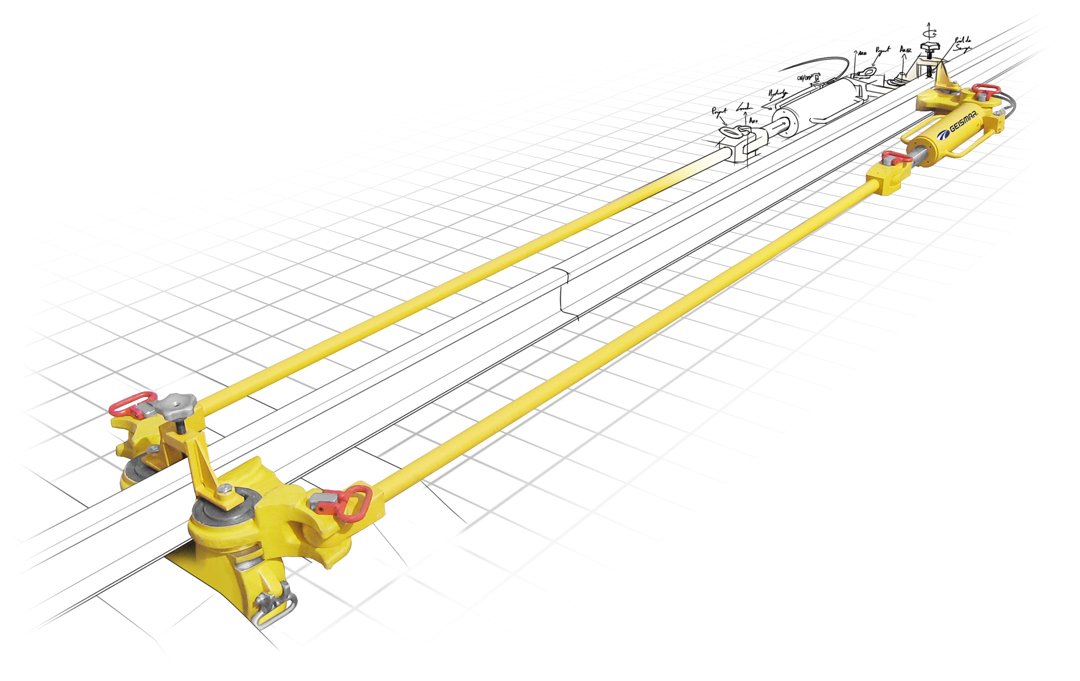

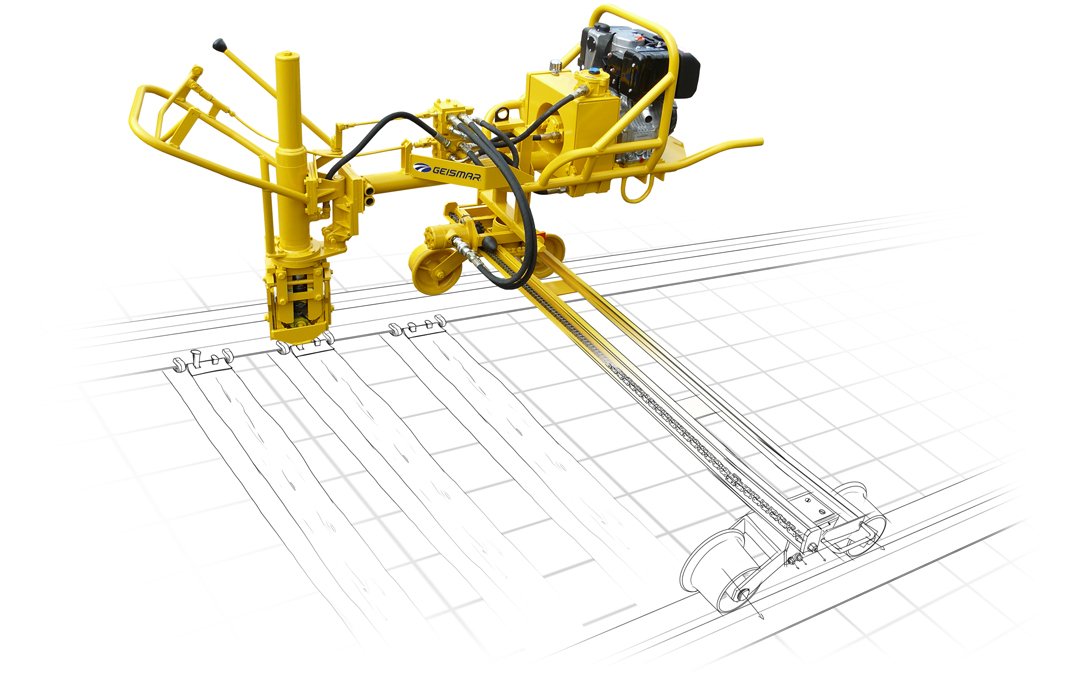

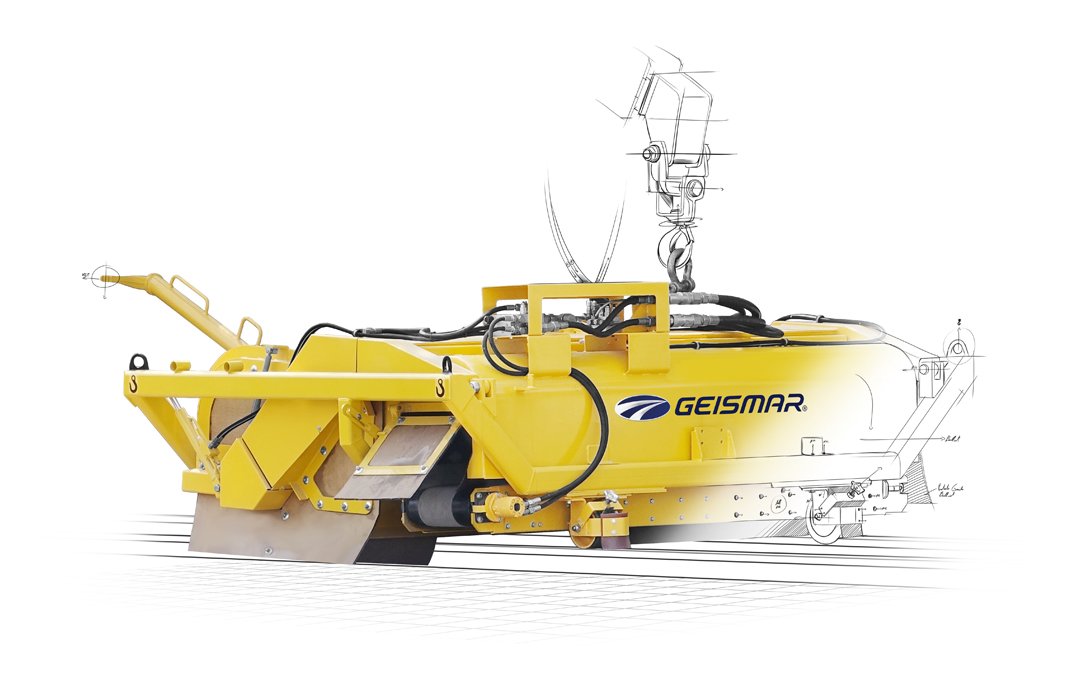

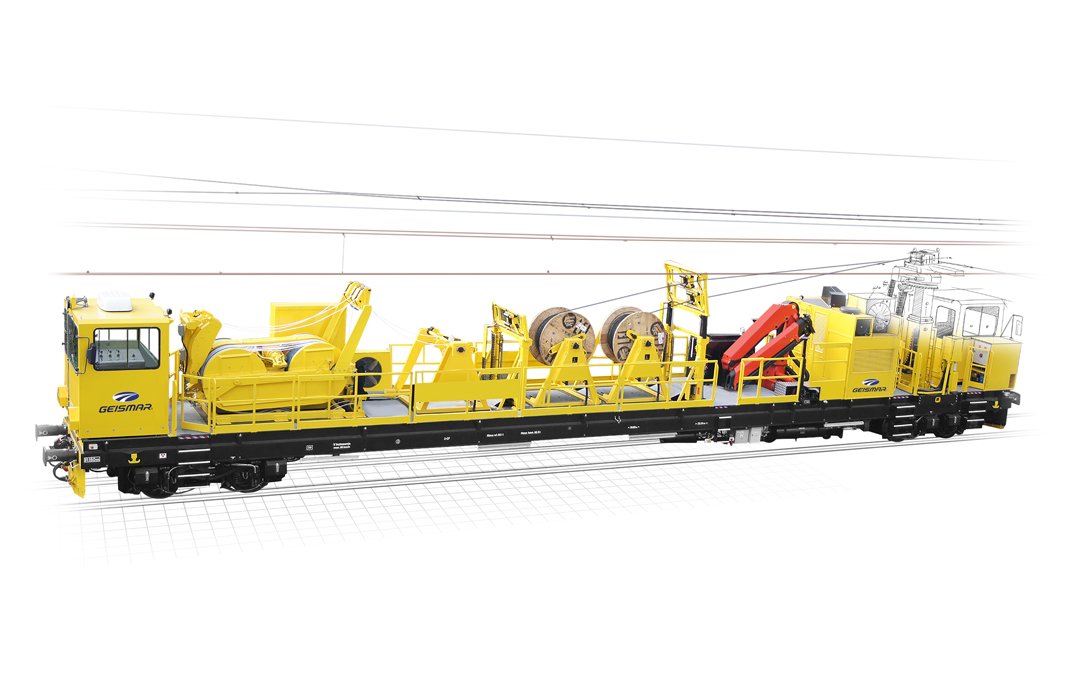

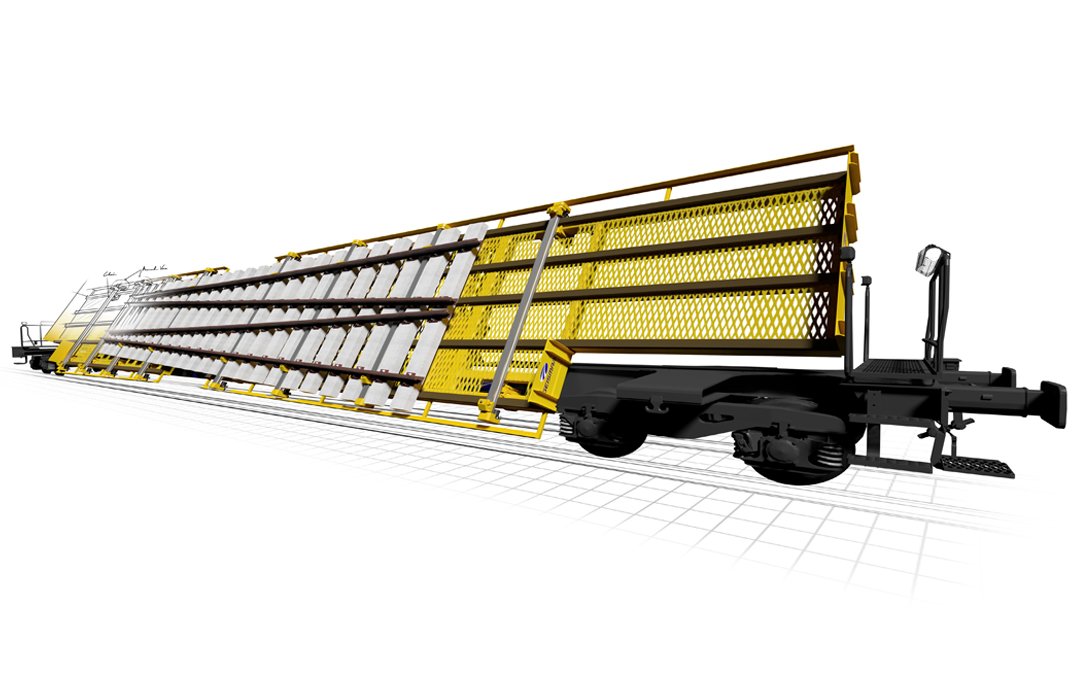

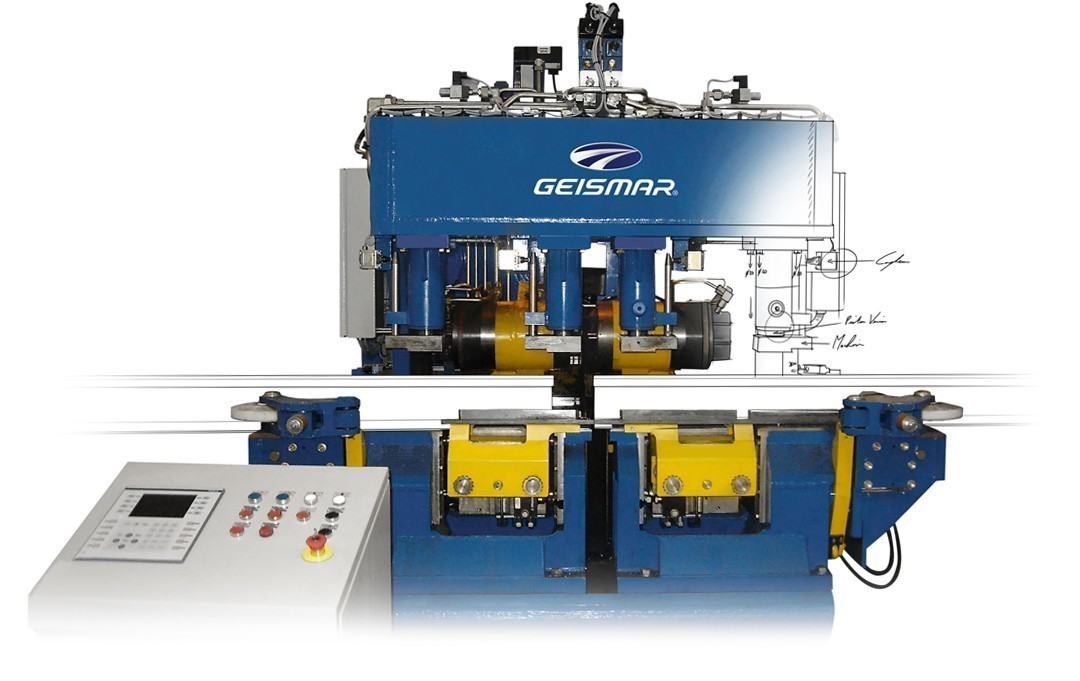

In order to lay new track with high productivity, the Rail Pulling System (STR) is an ideal solution to pull two rows of long welded rails from a wagon.

Initially chosen in 2016 by Colas Rail to build high-speed lines, a new option has recently been added to handle panels, concrete slabs or sleepers. A well-deserved evolution to continue building the global rail network at lower cost.

With a record for laying long welded rails set at 3,564 m in one day, the ECTR has proved its worth in the construction of the high-speed line in Morocco, between Tangier and Rabat.

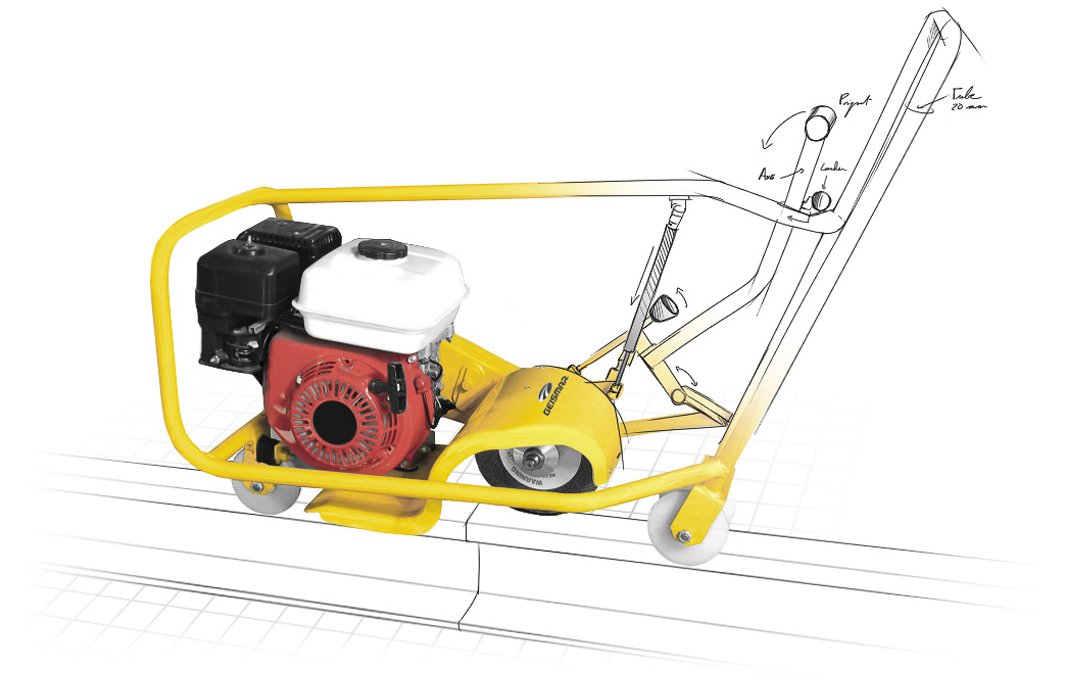

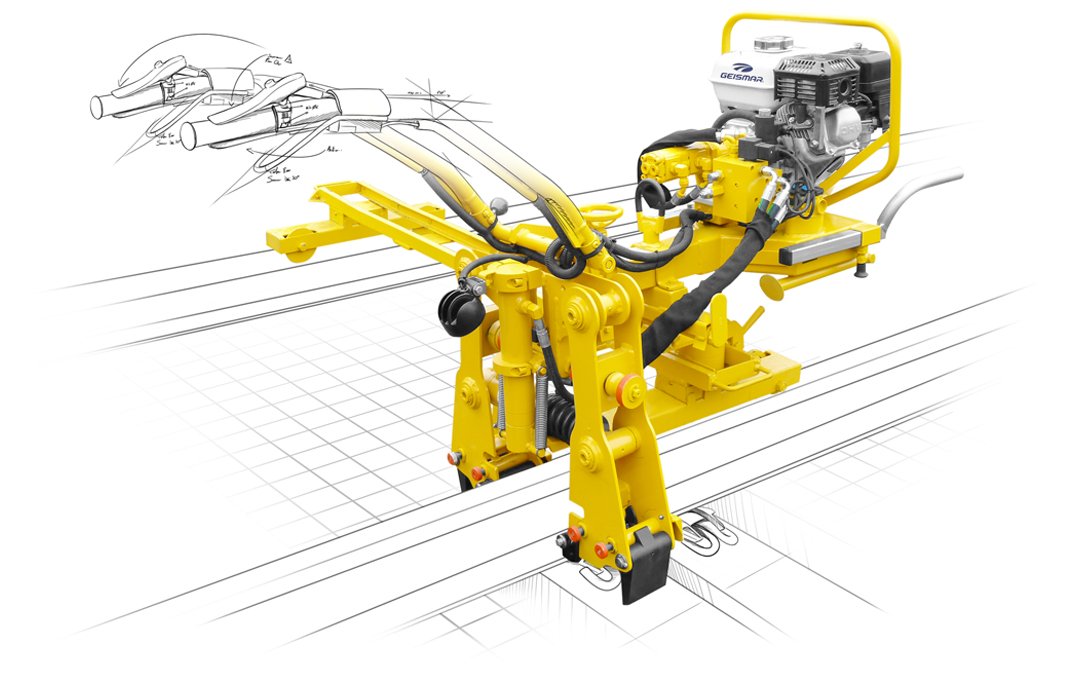

This system makes it possible to lay 432 m long welded rails from wagons. The rail pulling system (STR) is composed of several elements :

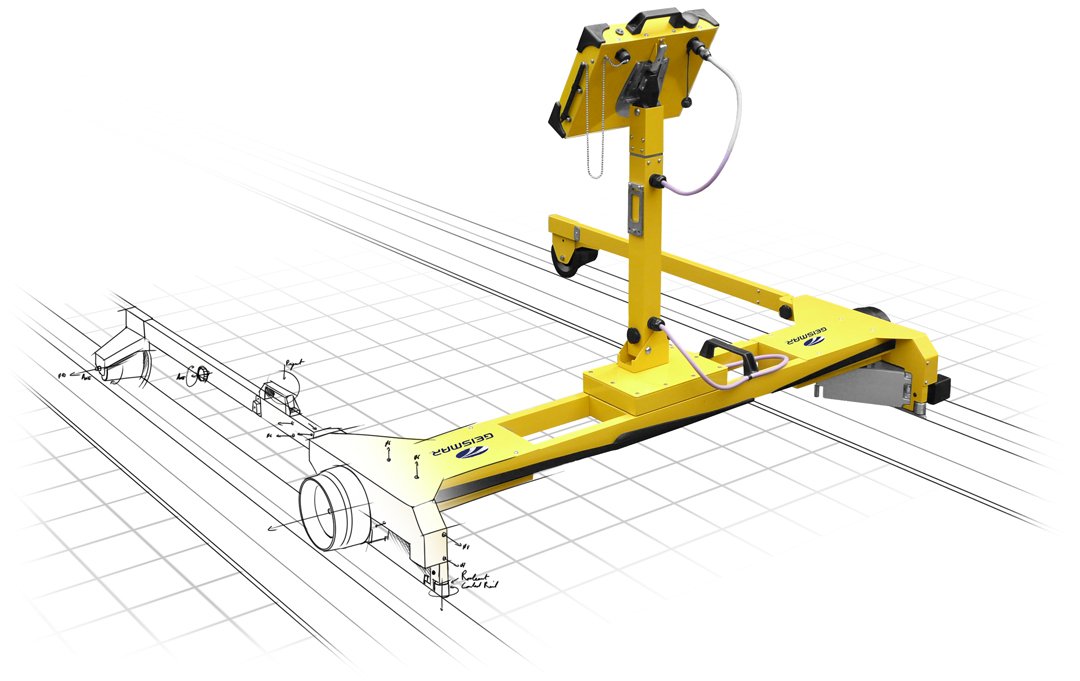

- A caterpillar gantry (ECTR)

- Guiding rollers on wagons (RGW)

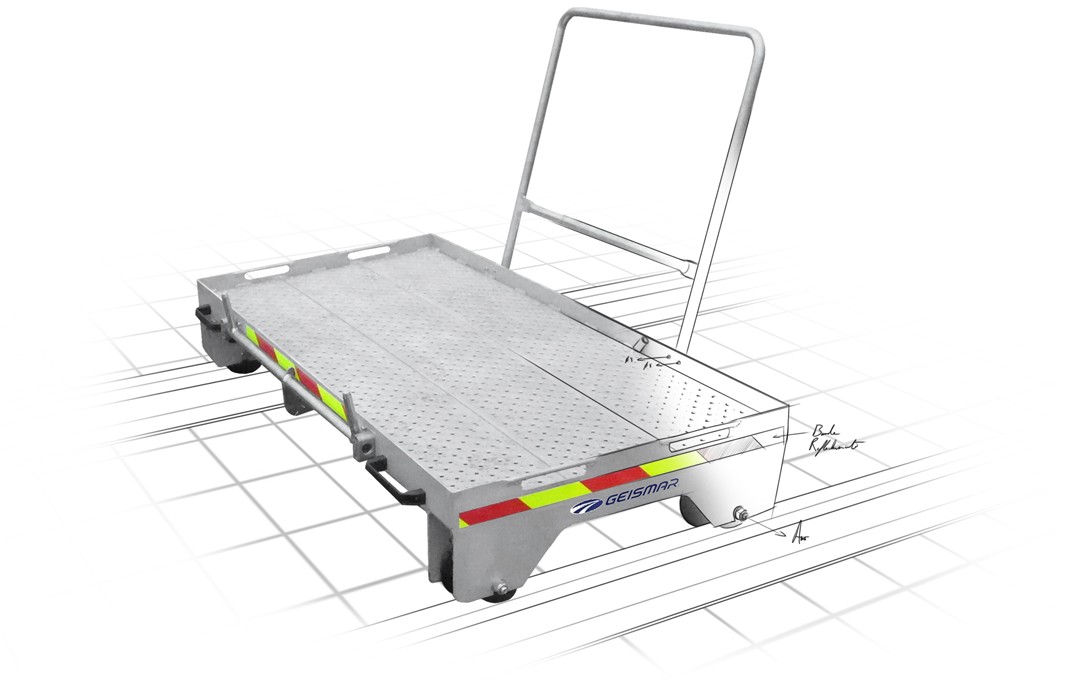

- Rail guiding trolley (LGR)

- Rail end trolley (LER)

- Rail guiding trolley (RR)

Although maximum safety is ensured (radio-controlled equipment, gantry stability, no operators on the wagon, rail guidance), the STR is mainly profiled to ensure high track laying performance:

- Installation carried out in less than one hour;

- No need for temporary track (ECTR equipped with tracks or rail wheels) ;

- Only one pass during the laying operation ;

- Autonomous in unloading, transport and installation.

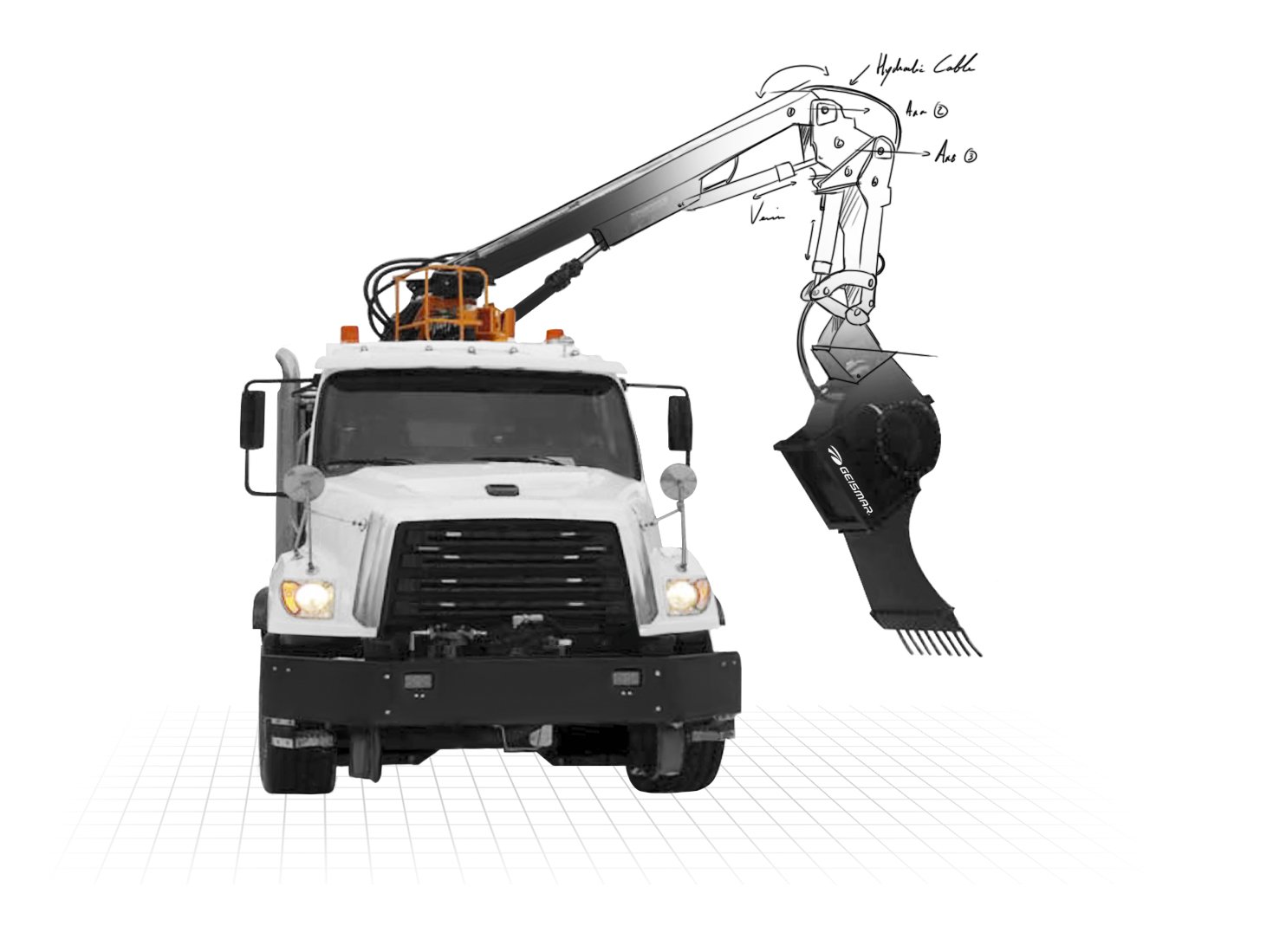

Much more flexible in its use than an installation train and with a greater load capacity than an excavator, the ECTR can work in sections thanks to its transport by truck or standard wagon.

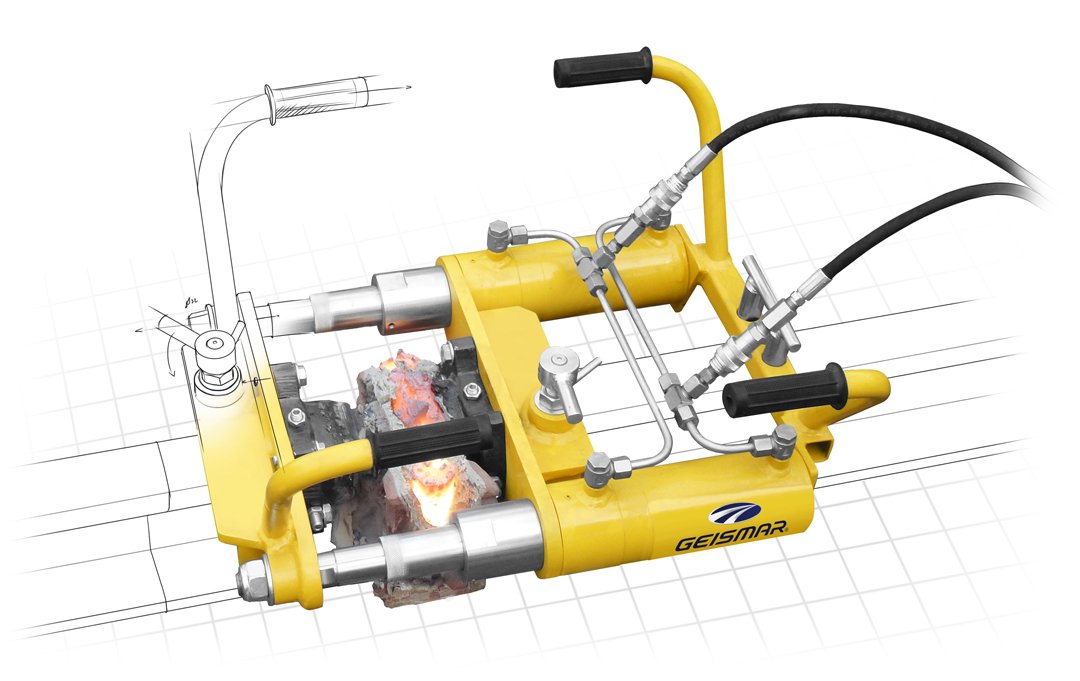

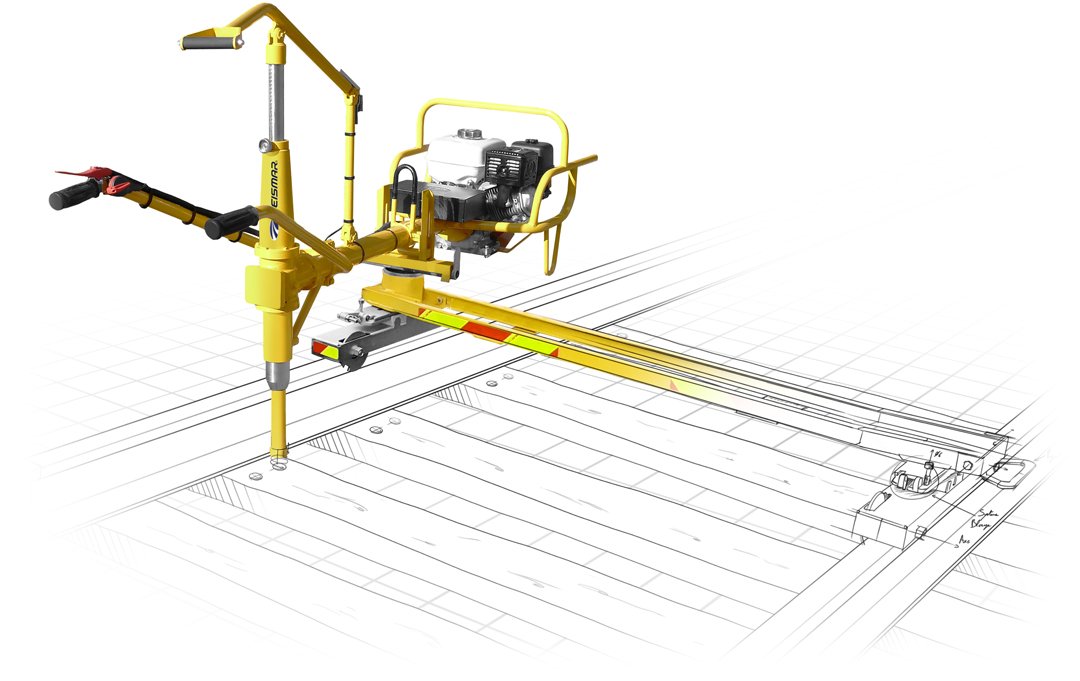

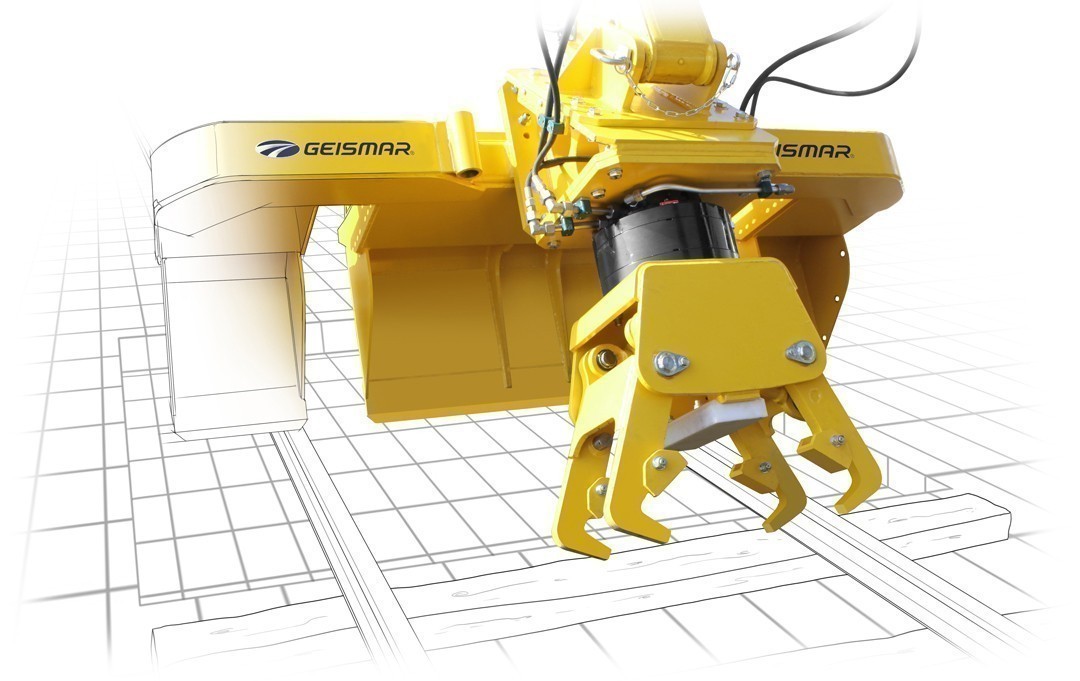

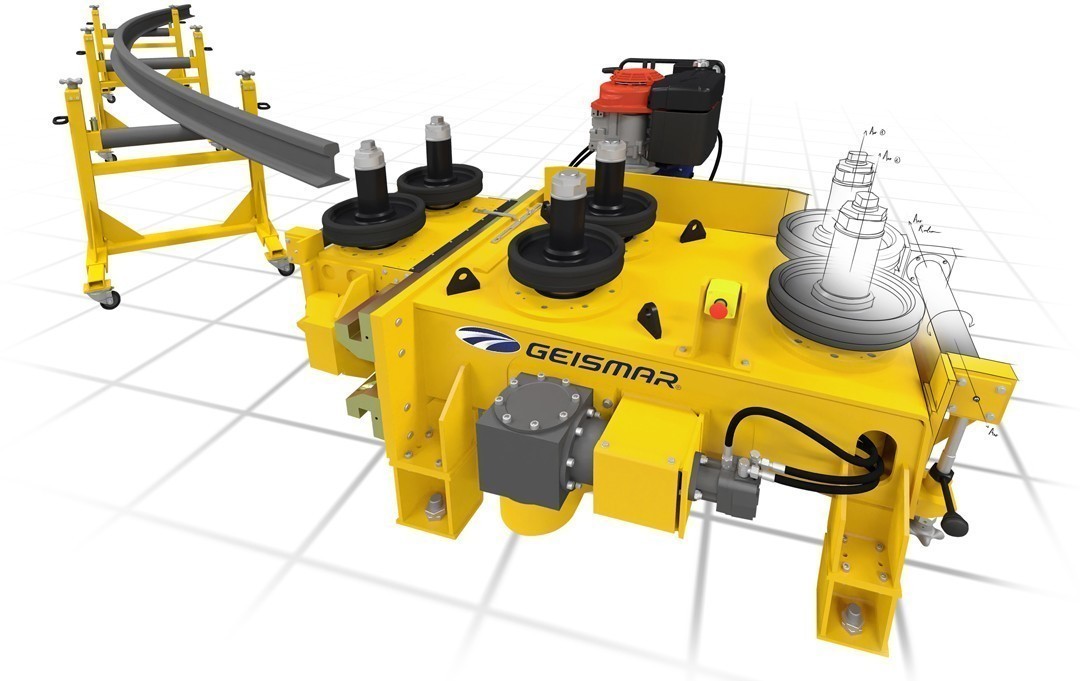

Initially limited to the sole function of pulling long welded rails, Colas Rail has ordered a new option that allows laying, to within 5 mm :

- up to 30 sleepers (fixed or variable sleeper spacing)

- up to 3 concrete slabs (dalle de 5,16 m x 2,4 m x 16 cm)

- track panels from 12 to 28 m

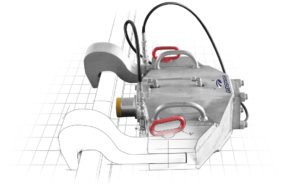

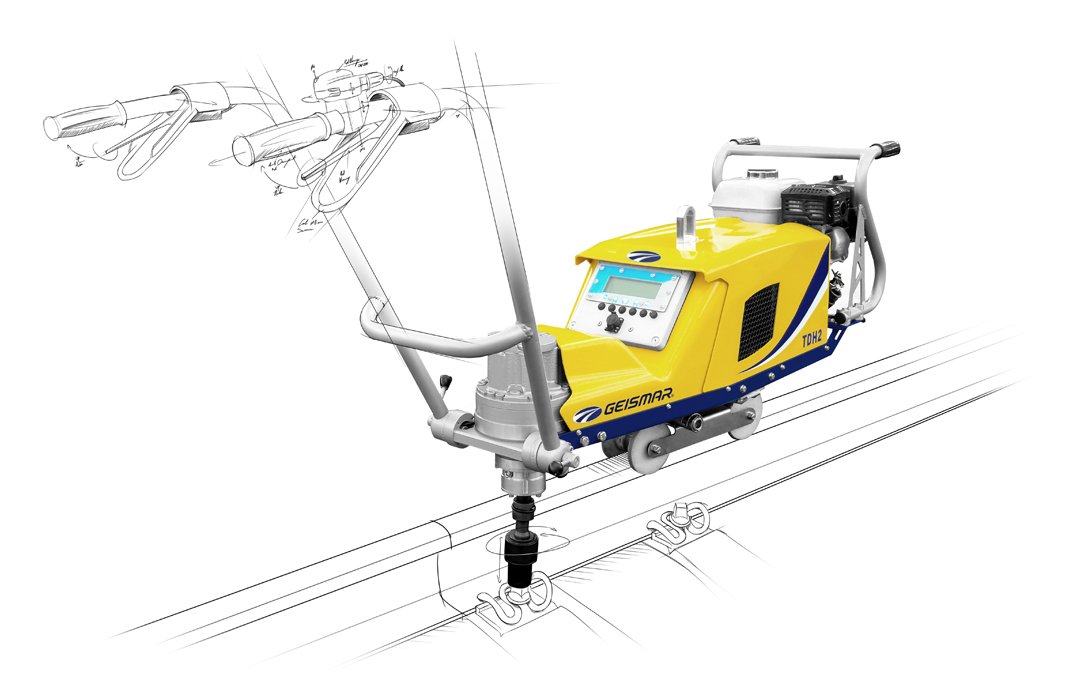

In order to achieve these objectives, the ECTR is equipped with a hydraulic spreader, fully radio-controlled by a single operator. Operations in the construction site area are carried out in complete safety by means of a removable driver’s station mounted on one side of the gantry. A visual assistance on a tablet, with the help of 6 cameras, finally improves the ergonomics of piloting.

Towing and lifting respectively up to 9 and 12 tons, the ECTR is therefore a modular solution combining safety, efficiency and economy of new track laying. It responds to the trend for modular construction sites (non-connected networks) and equipment (panels, rails, sleepers) while limiting investments.

Currently being delivered to Colas Rail, the ECTR therefore has some fine challenges to meet in the coming months. Let’s follow the worksites closely with Fréderic Ramirez, Track Laying Product Specialist (f.ramirez@geismar.com – 06 09 20 74 15)!

| See product sheet |

Se connecter

Se connecter