Geismar at the expertise meeting in Münster

Geismar, a world leader in track and catenary installation, renewal and maintenance equipment, will exhibit in Münster from Tuesday 31st May to Thursday 2nd June 2022 at the 28th edition of the IAF, the key event for rail professionals.

Geismar’s technical and commercial teams will meet with the railway industry and present a selection of iconic and innovative solutions and equipment, including a range of new electric and dual-mode machines.

Geismar’s ambition is to actively contribute to the new development of global rail transport by always providing our customers with safe, ingenious, efficient, sustainable and more environmentally friendly solutions.

The 5 pillars of the Geismar philosophy:

It has been 5 years since railway professionals have had the opportunity to meet in Münster. Geismar’s teams are therefore enthusiastically preparing to meet up with clients, experts and partners at the 28th edition of the IAF which will take place from 31st May to 2nd June 2022.

On this occasion, Geismar will present some of the machines that are most representative of the five pillars of the Geismar philosophy: equipment that respects the safety and wellbeing of operators, is perfectly adapted to the needs of our customers, allowing them to carry out quality work and achieve high productivity while minimising our impact on the environment.

“We are delighted to be able to meet our customers again in the typical railway setting of Münster. The IAF is an important meeting place for all rail professionals and goes far beyond the exhibition of machines: it is a catalyst of initiatives, an accelerator of projects where companies like Geismar draw on their expertise to propose new solutions. Our ambition is to draw on our expertise and on our 5 pillars strategy to accompany our customers and to contribute together to the building of modern, safe, efficient and environmentally friendly transport networks.”

Alexandra CURIEL, Managing Director of Geismar Group.

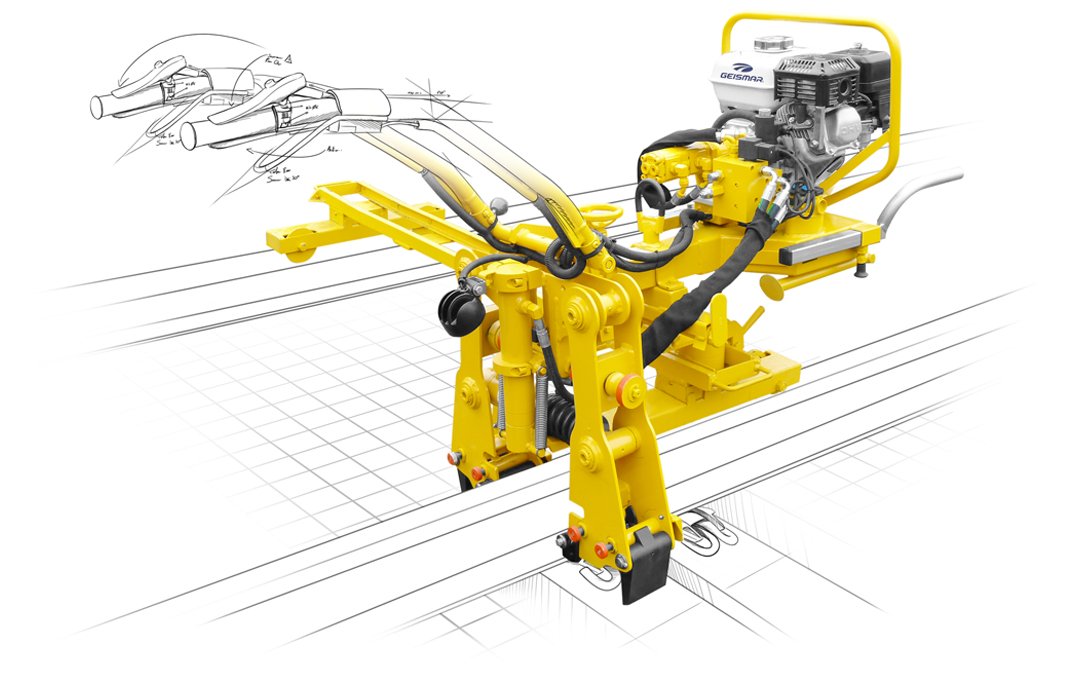

Three systems embodying the Geismar philosophy will be presented in Münster:

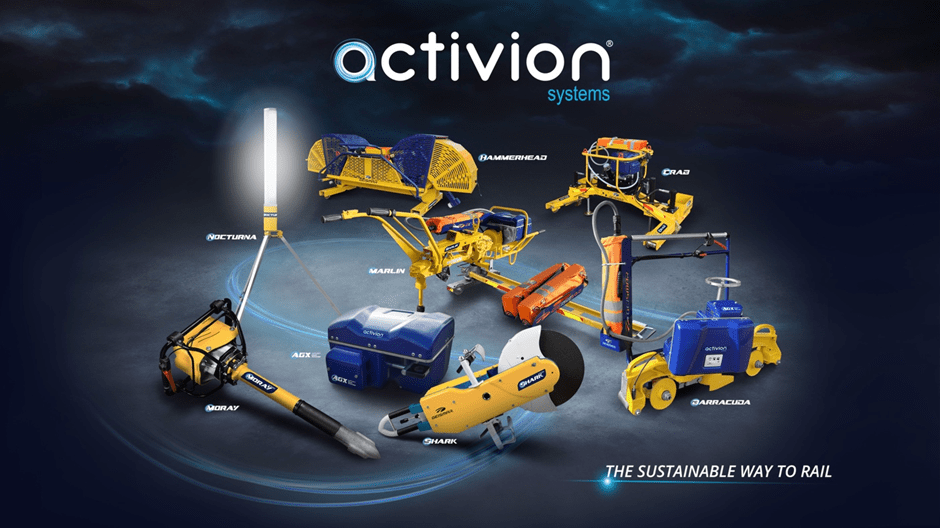

Activion® Lineup

The activion® range of battery-powered machines, which, thanks to its scope and unique interchangeable battery system, provides a practical, versatile and effective solution to the health and environmental problems of railway work. The activion® range allows all track clearance operations to be carried out without emitting harmful gases, while significantly reducing noise pollution.

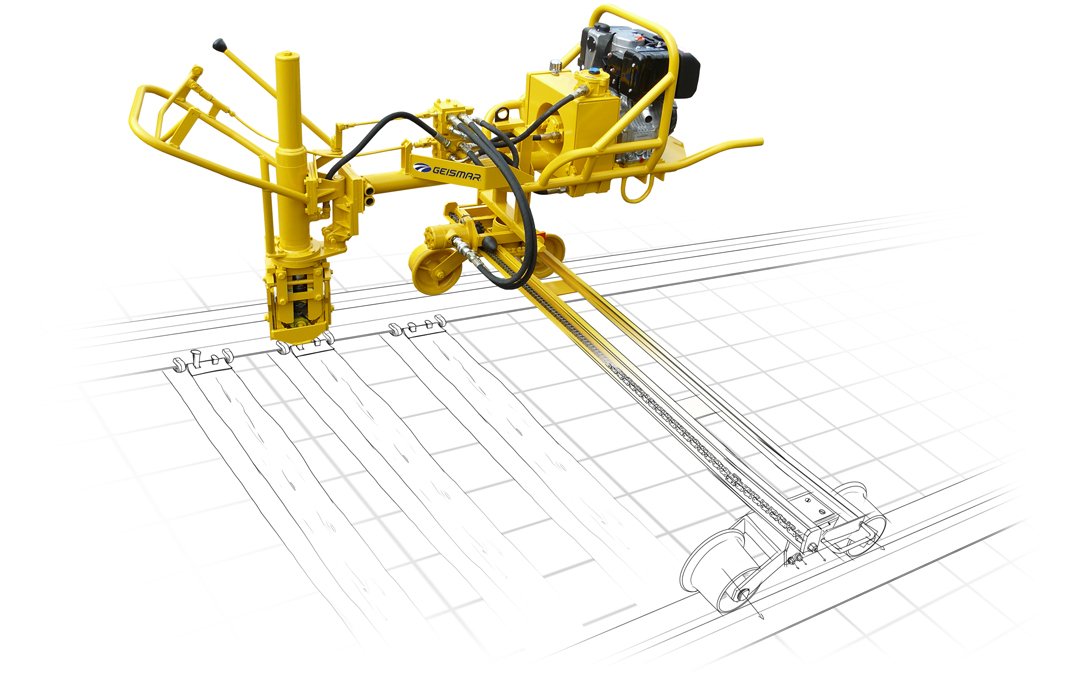

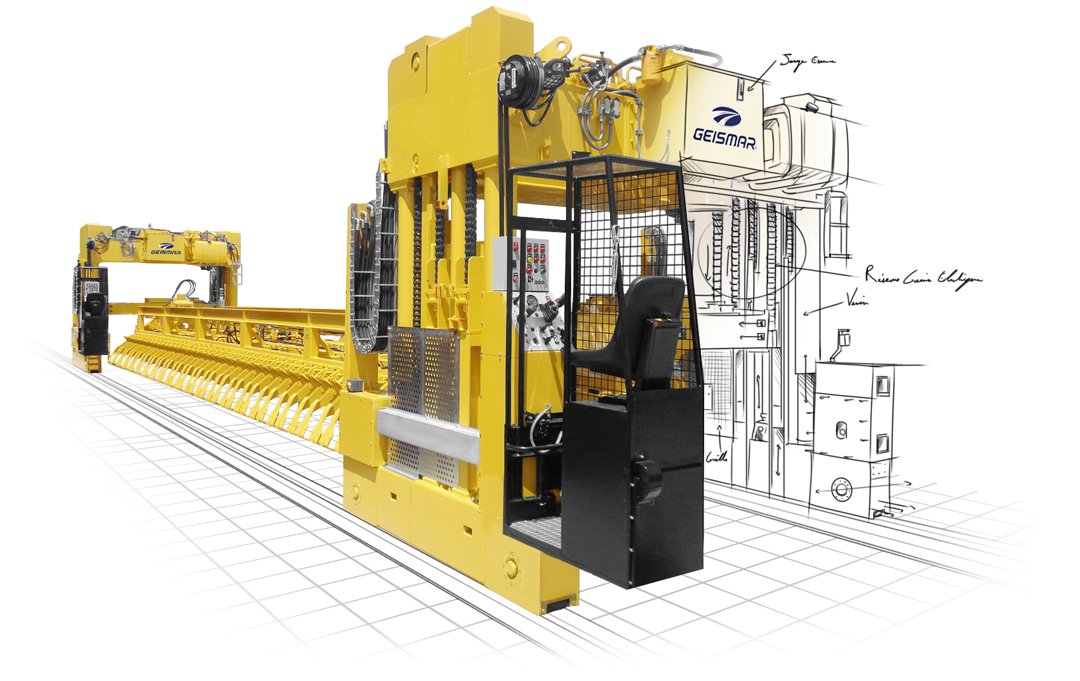

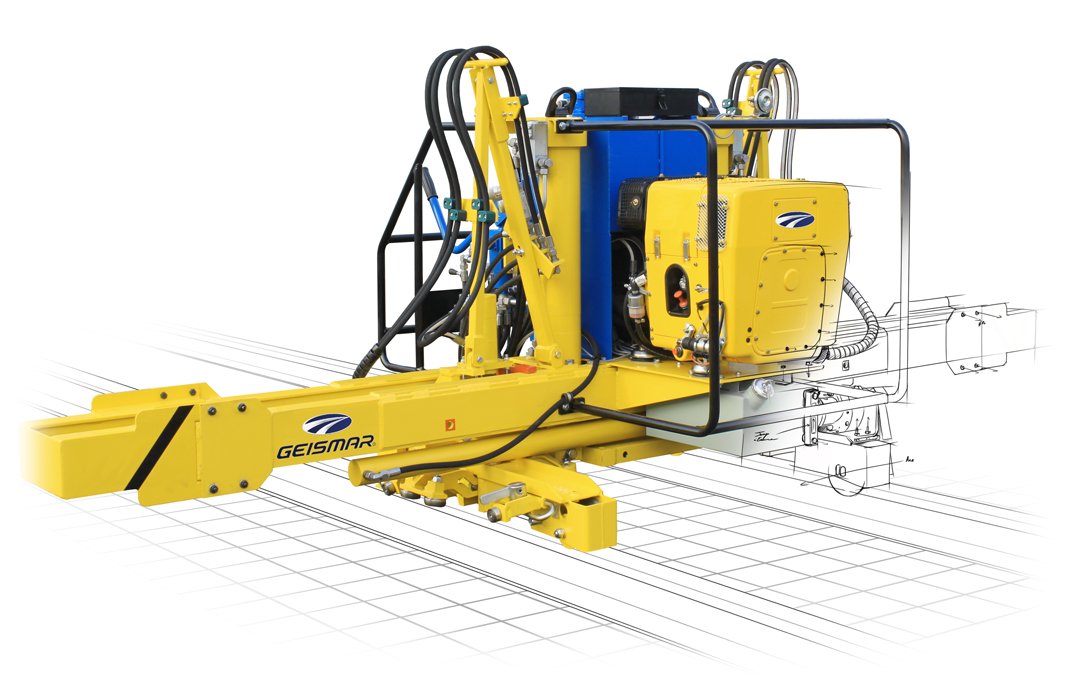

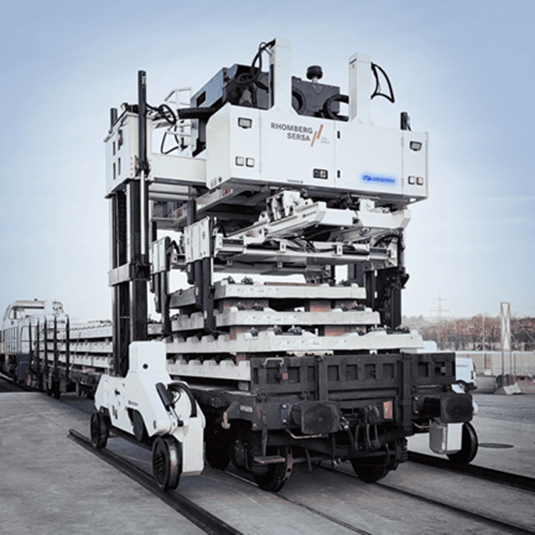

Tectonic ECTR

The new ECTR radio-controlled tracked machine is the Swiss Army knife of track laying. Robust, compact and versatile, the ECTR can be used to pull rails, lay sleepers, concrete slabs or complete track panels even in narrow environments such as tunnels. It can carry up to 20 tons of load running either on caterpillars or on rails. The ECTR is a machine that is very representative of Geismar’s multi-functional approach and the many benefits that customers can derive from it. |  |

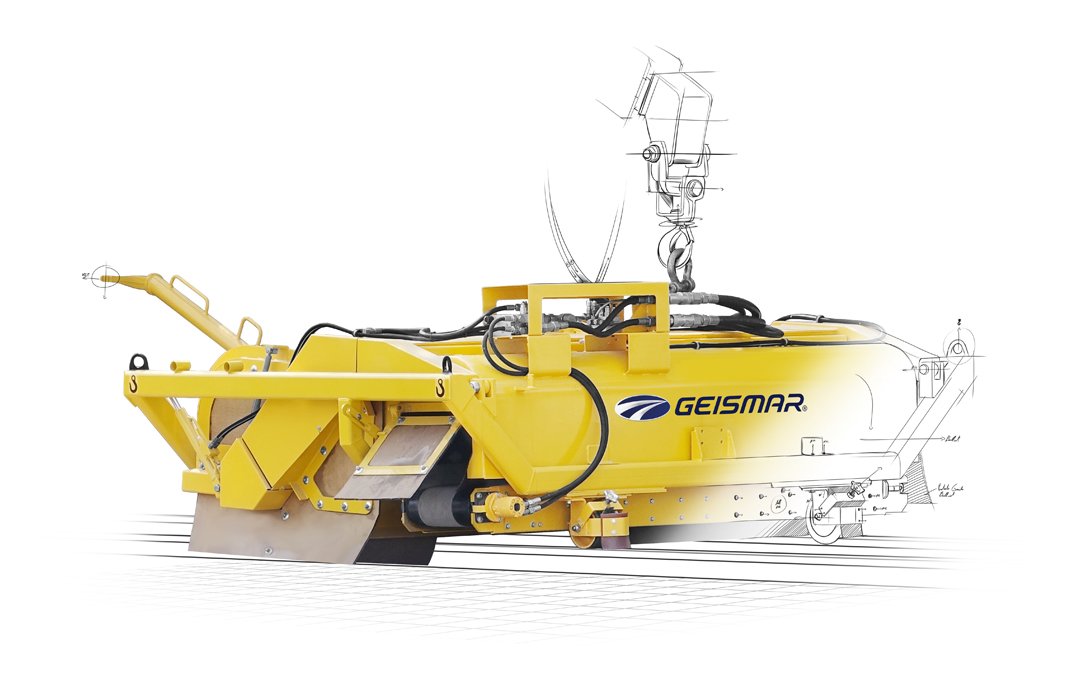

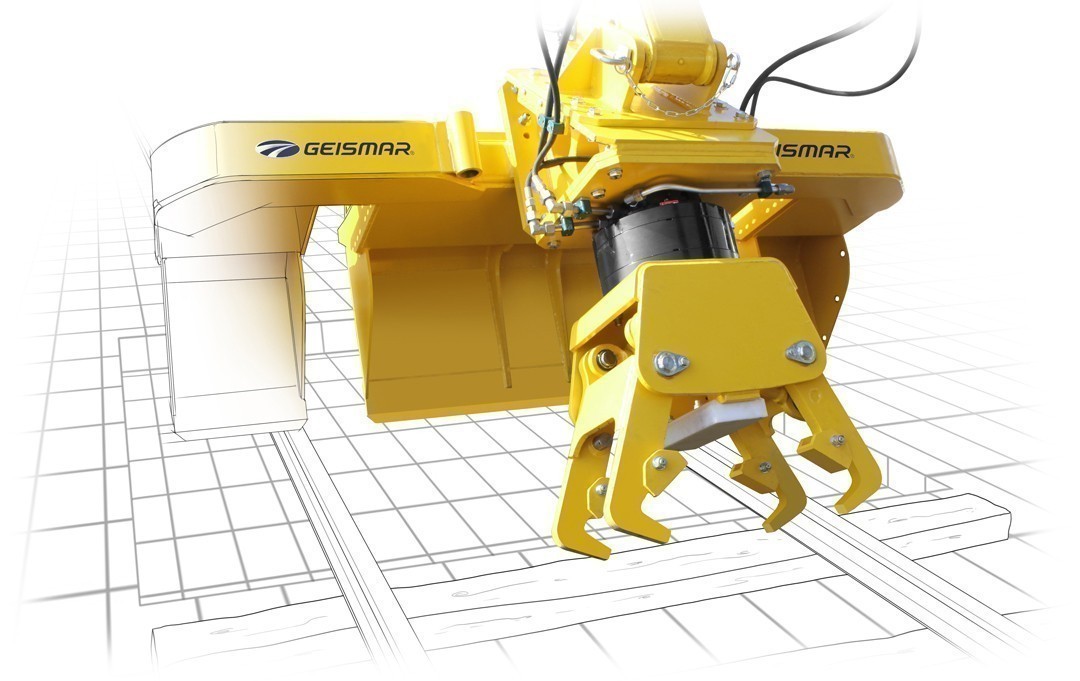

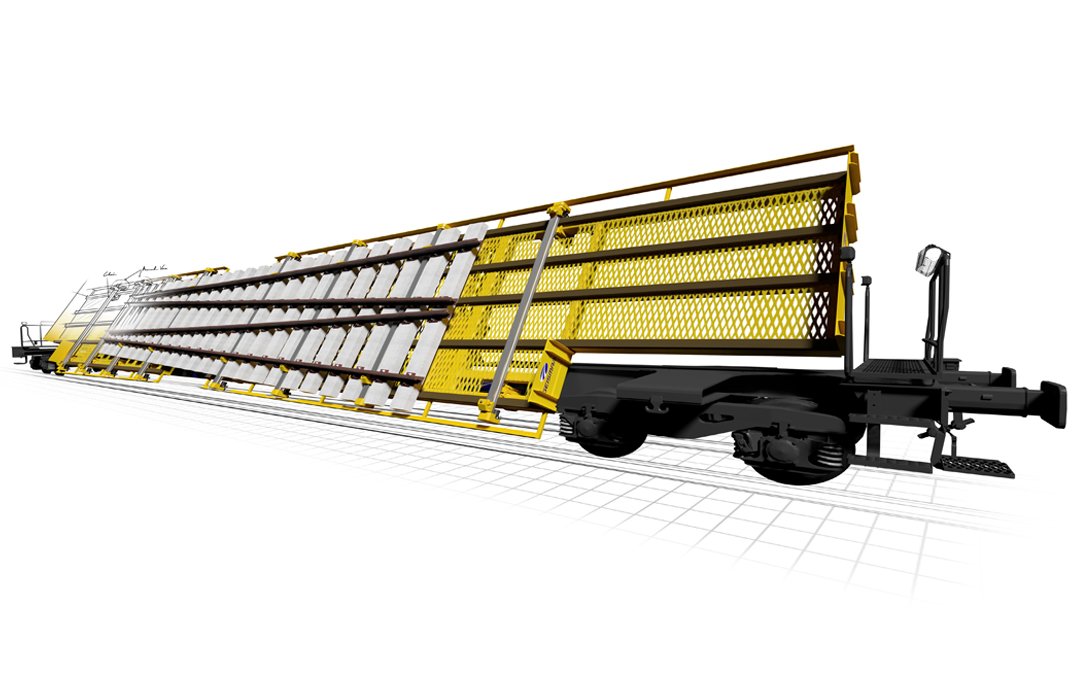

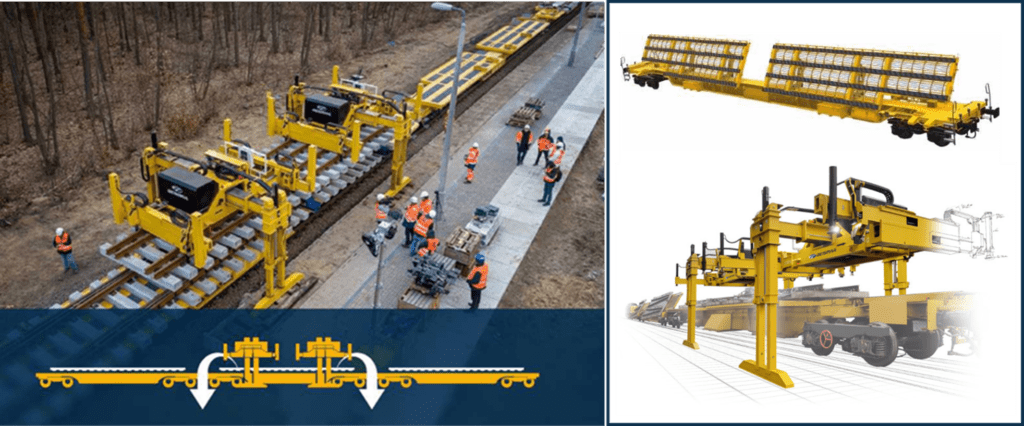

Tilting Wagon + PWP

In cooperation with our Polish partner KZN Bieżanów Group, Geismar presents the combination of a tilting wagon and a PWP gantry crane, which enables the safe transport and handling of pre-assembled switch sections. This system enables large turnouts to be transported, unloaded and laid with great precision. This combination offers a particularly suitable solution on a complex construction site where one cannot rely solely on the implementation of the Geismar PEM-LEM system. Highlighting the partnership between Geismar and KZN is particularly relevant this year as the IAF has chosen Poland as the country of honour for this 28th edition.

Solutions designed for each type of network:

All the solutions devised by Geismar’s engineering offices not only benefit from our know-how, which has been proven in the railway world for almost a century but are also adapted to the particular issues of each type of network.

Through experience and trusting relationships with our clients, our engineers understand that the challenges of building or maintaining urban rail networks are different from those faced by high-speed rail operators, which are themselves distinct from the problems associated with conventional networks or mining and industrial railways.

This is why we offer our customers a dedicated approach to their problems and a set of solutions perfectly matched to each phase of construction, renewal or maintenance. We have grouped these dedicated solutions into 4 product ranges:

Solutions for urban networks

Solutions for high-speed lines

Solutions for traditional networks

Solutions for industrial networks

Visitors to the Geismar stand will have the opportunity to discover a selection of solutions for each type of network in dedicated corners and brochures. They will also be able to discuss with our product specialists and identify the machines or systems likely to best meet their needs.

In this respect, more than just “suppliers”, Geismar’s engineering teams act as true consulting partners capable of guiding and supporting our clients in their technical choices.

“Our business as equipment designers and manufacturers is evolving with the increasingly global consideration of the environment. We support our customers in the implementation process of the machines, integrating the environment of the worksites to optimise performance and yields, all this with a constant concern for the fairest cost. We also pay particular attention to the “man/machine” interfaces and our range of carbon-free machines reduces noise levels and emissions of harmful particles, thus making a decisive contribution to the health and well-being of site operators.”

Xavier GAULTIER, Technical Director Geismar Group.

Geismar, pioneer in the electrification of railway equipment:

In addition to the wide variety of machines already in the catalogue, Geismar’s R&D teams continue to think and innovate to help our customers develop the railway equipment of tomorrow.

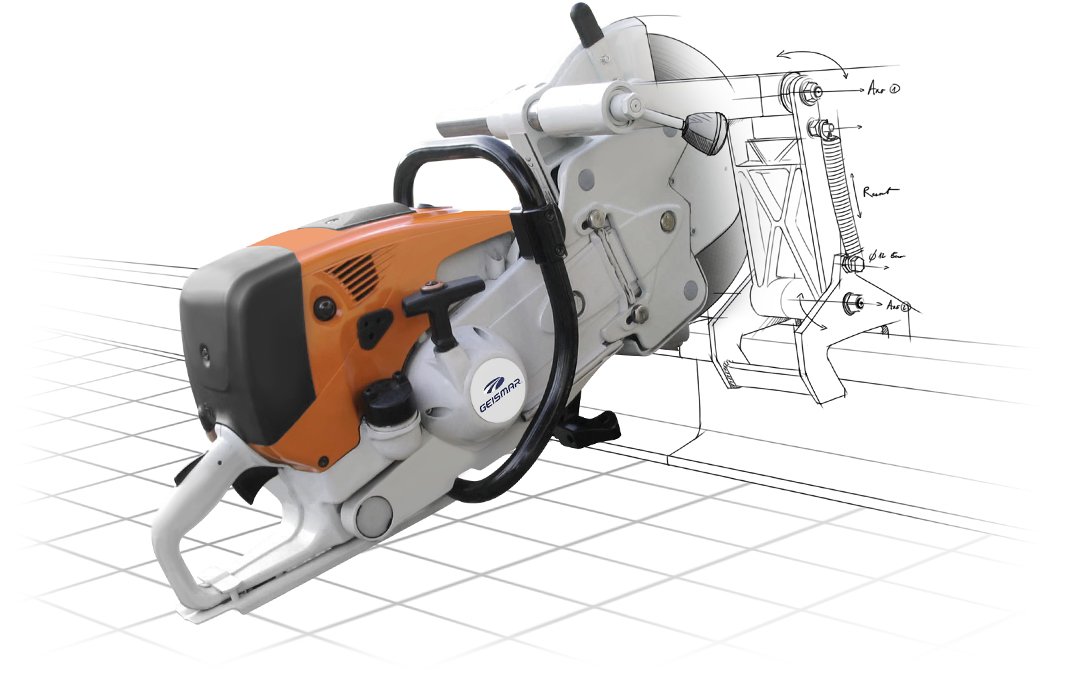

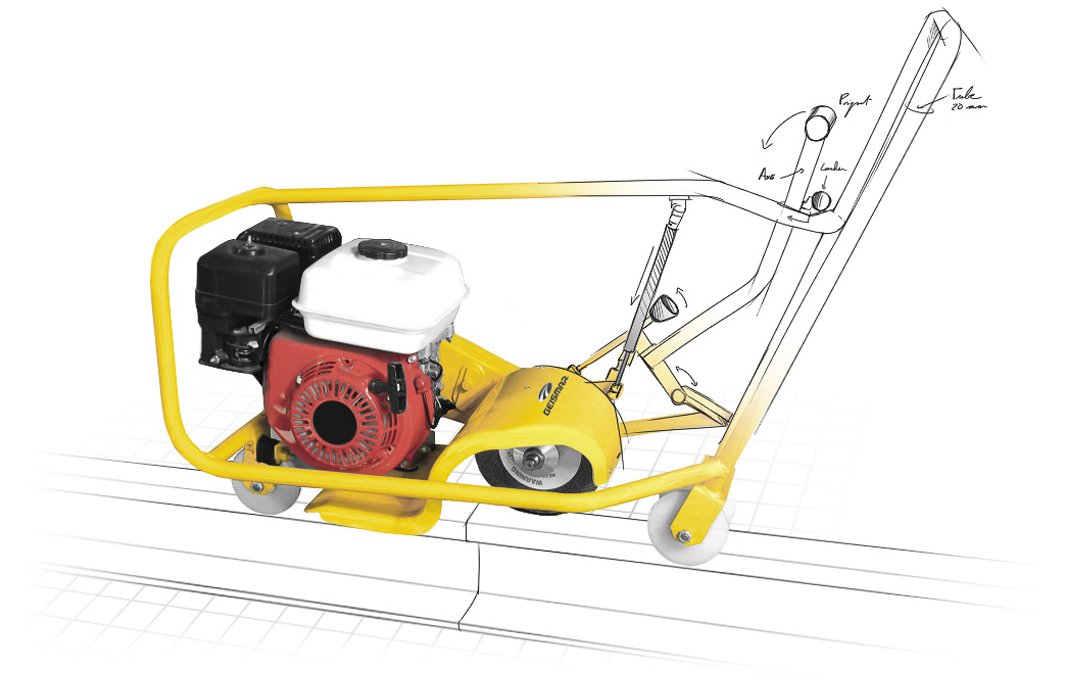

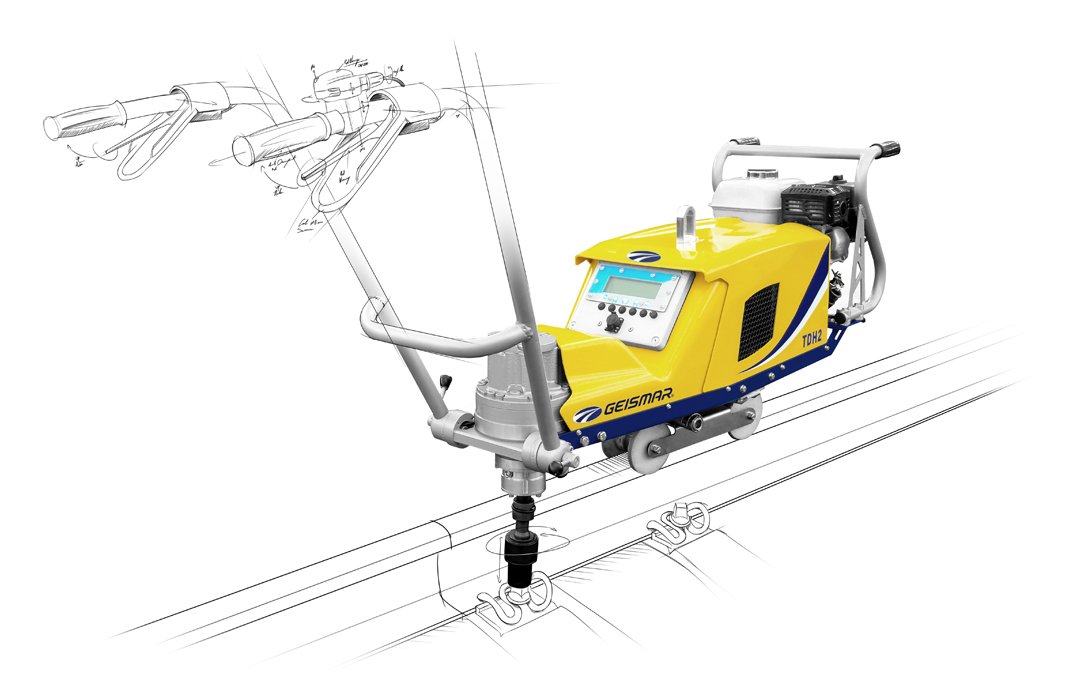

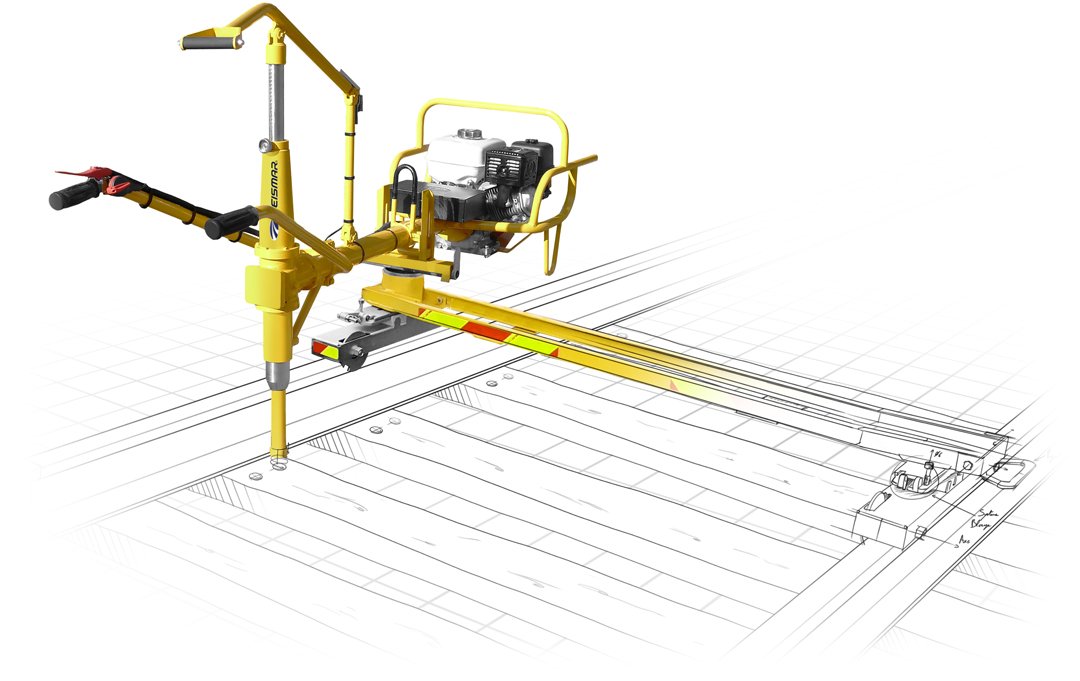

Given the urgency of the energy transition, of which the railways will be one of the main players, the demand for electrical equipment should grow very strongly over the next few years. Geismar has anticipated this trend and already offers a complete range of small 100% electric machines, the activion® range, which will be exhibited in Münster. Visitors to the Geismar stand will be able to see demonstrations of the activion® “Shark” electric disc cutter and the activion® “Barracuda” electric grinder.

The unique UN38.3 certified battery with a capacity of 1.4 kWh is one of the main advantages of the activion® range. All activion® machines are powered by this same version of the battery. This facilitates the sharing of power between different machine types – one battery can be used for several tasks – and radically simplifies the management of recharging, transport and storage as all batteries are interchangeable and compatible with all machines. This makes life on work sites much easier. In addition, a downloadable smartphone application makes it possible to connect to the battery via Bluetooth and check its state of charge.

|  |  |

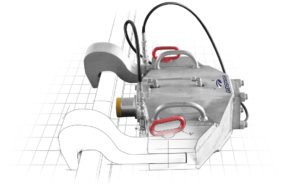

A “Retrofit” workshop will also show the few steps to convert existing light machinery to electric power with the AGX adaptation kit. This innovative solution is proposed by Geismar for an ecological and economical approach to the energy transition: no need to replace a whole machine to go electric, just substitute the AGX electric motor for the old combustion engine.

The activion® range of machines offers many direct advantages for operators (easy start-up, less noise, less vibration, zero emissions, simplified maintenance, greater flexibility) but also for contractors with reduced operating costs (fuel, lubricants, maintenance) and greater peace of mind in the face of increasingly stringent noise and emission standards.

In addition to this range of light machines, Geismar also offers rail, road-rail and dual-mode (methane + electricity) vehicles such as the Air Wizard truck presented in Münster. Equipped with a scissor platform and designed to work on catenary, this ultra-versatile truck (rail-road + gas-electric) is the property of Nantes Métropole. The Société d’Economie Mixte des Transports en Commun de l’Agglomération Nantaise (SEMITAN) operates it as part of the maintenance of the vast tramway network which enabled Nantes to earn the title of “European Green Capital” in 2013, thus entering the top league of fellow green cities such as Stockholm and Hamburg.

Other clean and innovative Geismar electric vehicles are currently being tested in Canada for the Société de Transport de Montréal (STM).

| The design, manufacture and commissioning of electric or dual-mode machines is one of the technological skills developed by Geismar in recent years. Beyond the simple change of energy, electrification opens new perspectives in terms of compactness, flexibility and equipment architecture. These are all possibilities that our engineers are actively exploring to invent new machines that are more mobile, more versatile, more efficient and safer.This makes Geismar the partner of choice for all networks and contractors mindful of the well-being of their employees and the impact of their activities on the environment. |

“The reduction of all kinds of nuisances on construction sites, for operators as well as for the surrounding population, is a constant concern for our engineering offices. We are working to decarbonise our machines and offer complete worksites, such as the removal of long welded rails for example, by equipment that is not relying on combustion engines at all.”

Xavier GAULTIER, Technical Director Geismar Group.

From small lightweight machines to 50-ton vehicles, a wide range of solutions:

Geismar distinguishes itself from its competitors by the extent of its range of solutions, reflecting a thorough knowledge of the railway industry and the trust placed in us by our customers, who rely on Geismar’s expertise for all types of work, from installation to inspection and from renewal to maintenance of tracks and catenary.

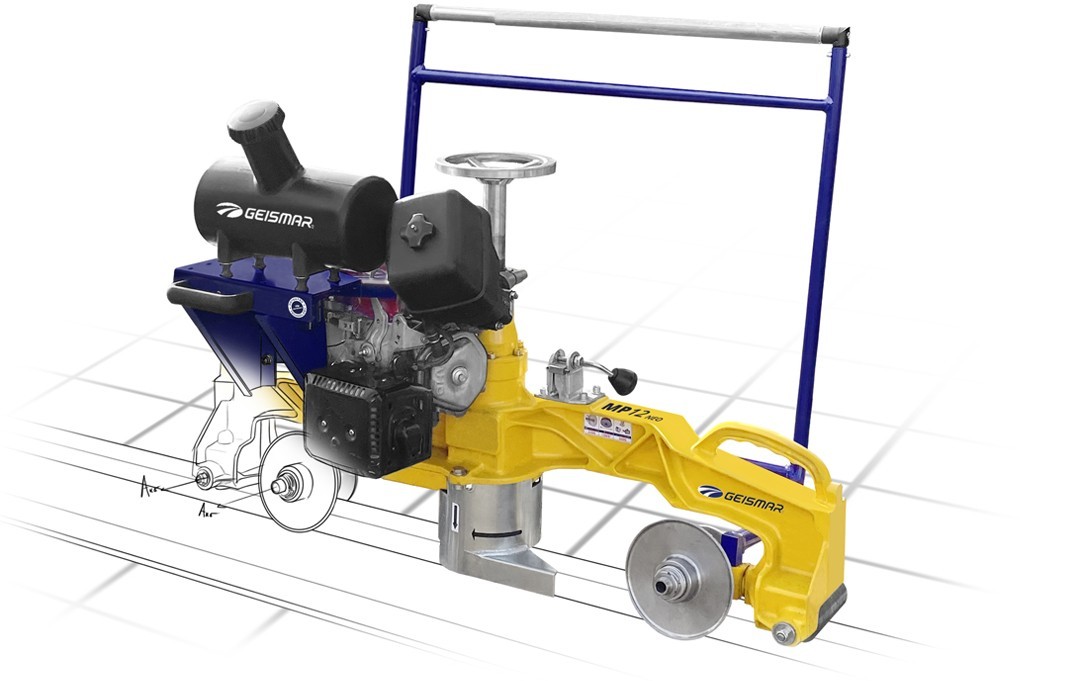

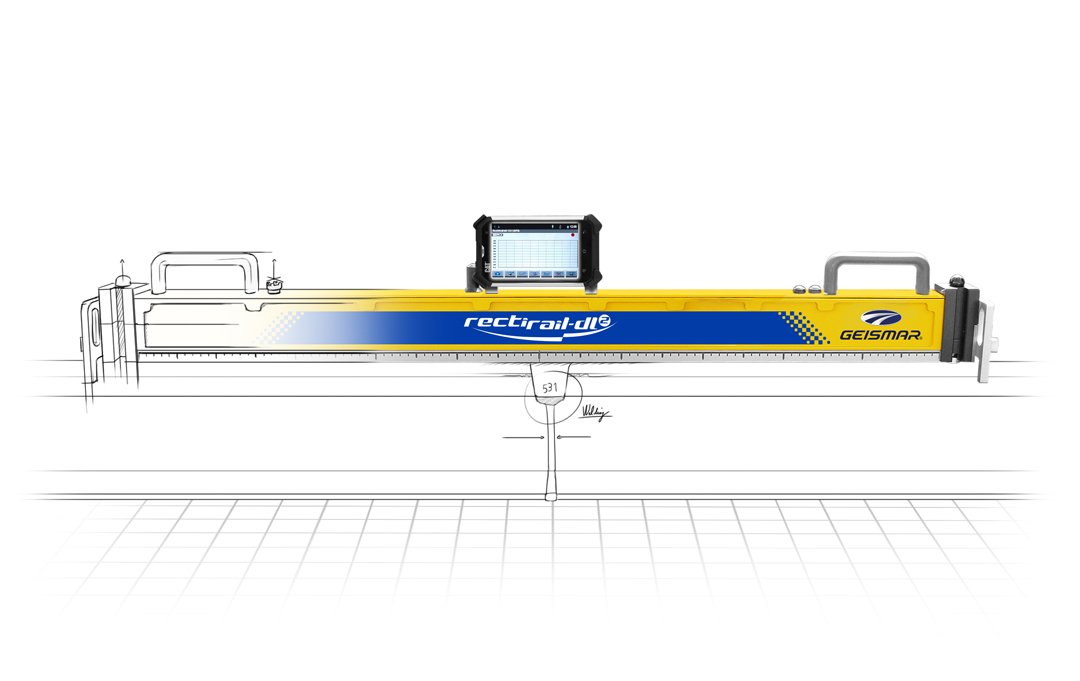

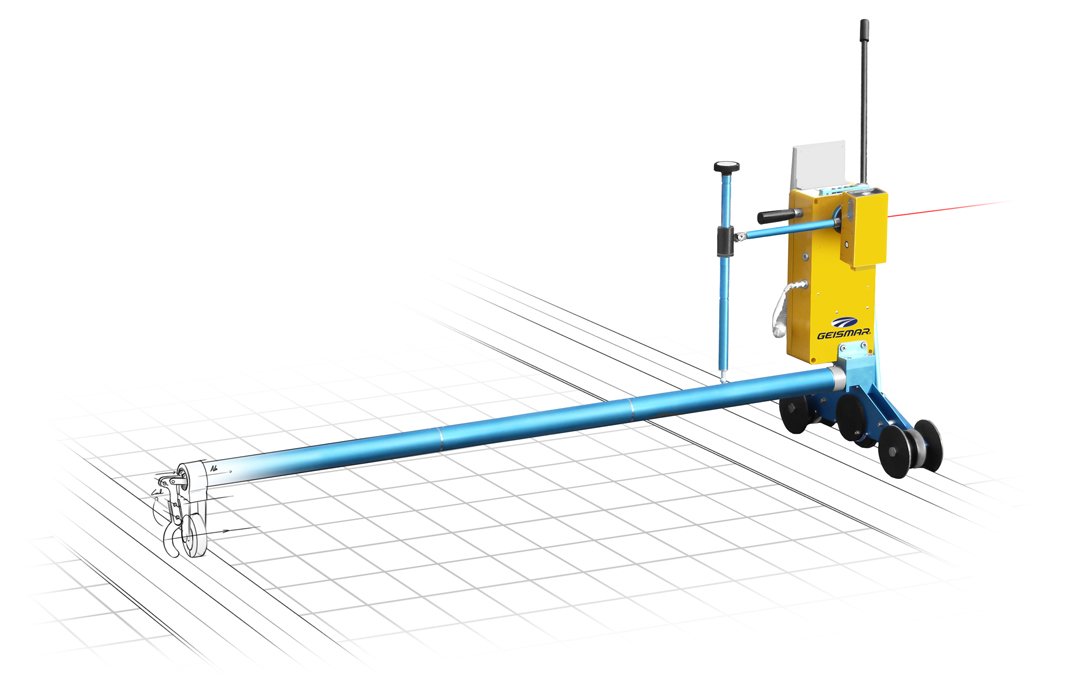

In addition to the activion® range of lightweight electric machines, Geismar will be presenting a large part of its range of manual and towed measuring equipment in Münster, as well as the new generation of Metal Hornet MP6 NEO, MP8 NEO, MP12 NEO and MV3 NEO grinders.

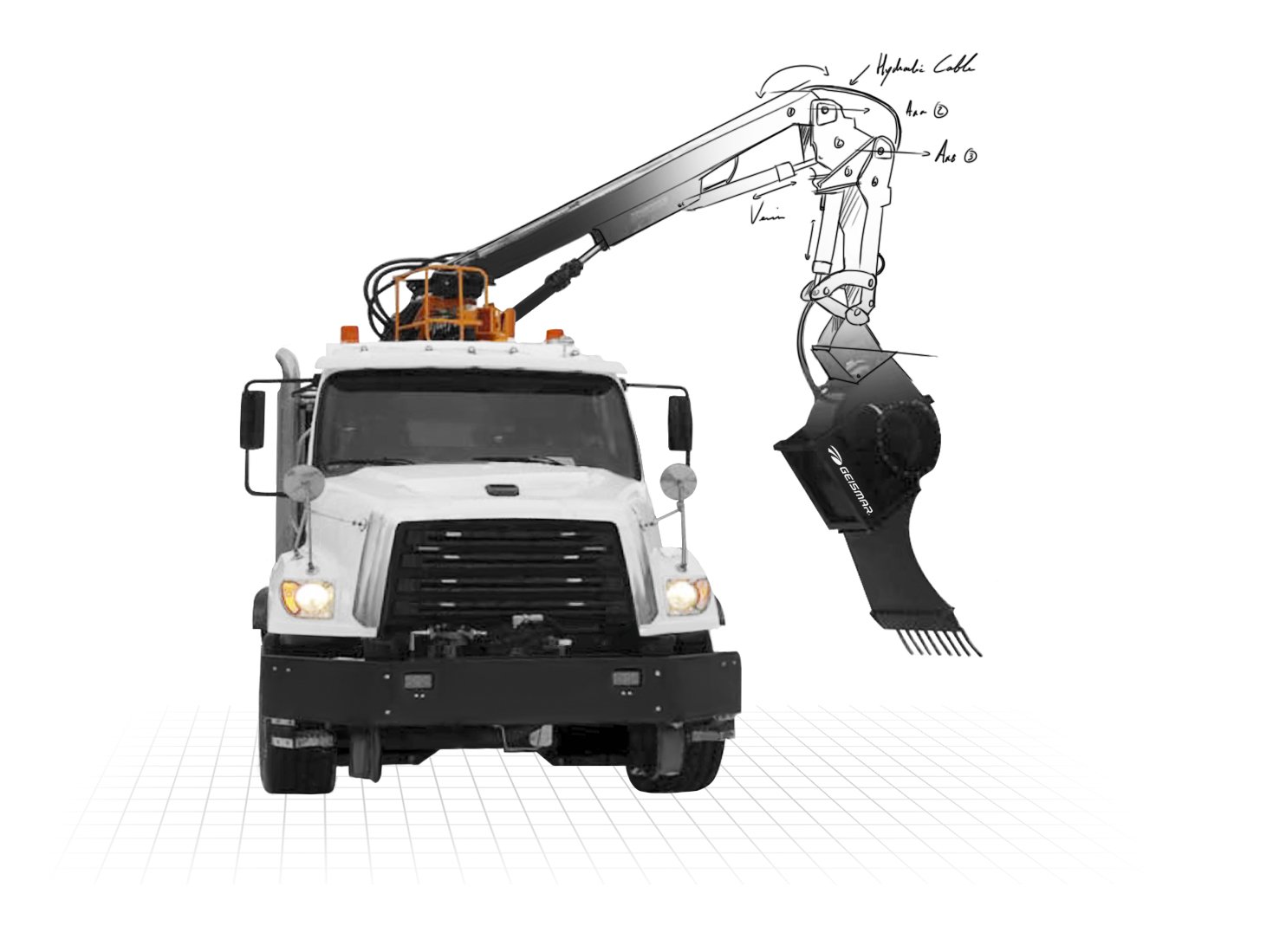

The Geismar KGT 280 road-rail loader is a reliable and powerful machine, specially designed for railways, which has already proved its worth on numerous construction sites around the world.

The KGT 280 will be presented alongside two of the accessories it can be used to operate:

• The MB8 AC tamping unit,

• The BRV track brushing tool.

|  |  |

Finally, although Geismar has chosen not to exhibit a tracked vehicle at this edition of the IAF (regular visitors will remember the impressive Infrabel tracked vehicle presented in 2017), this is nevertheless a fast-growing activity for our brand, with some very fine projects currently being built or commissioned, such as :

• Catenary maintenance vehicles for Deutsche Bahn,

• Catenary Inspection and Maintenance vehicles for the New Jersey Transit Authority,

• Optical track inspection vehicles for Irish Rail.

“Over the years, Geismar has built up a unique and unrivalled offer to meet all the needs of its customers in the fields of installation, maintenance, renewal and control of railway infrastructure. Today, our Activion® electrical range allows us to maintain our leadership in all market segments while making strong progress on the notion of sustainable development, which is increasingly important to our customers and partners.”

Rudy HAYAT, Commercial Director Geismar Group.

Innovation for flexibility:

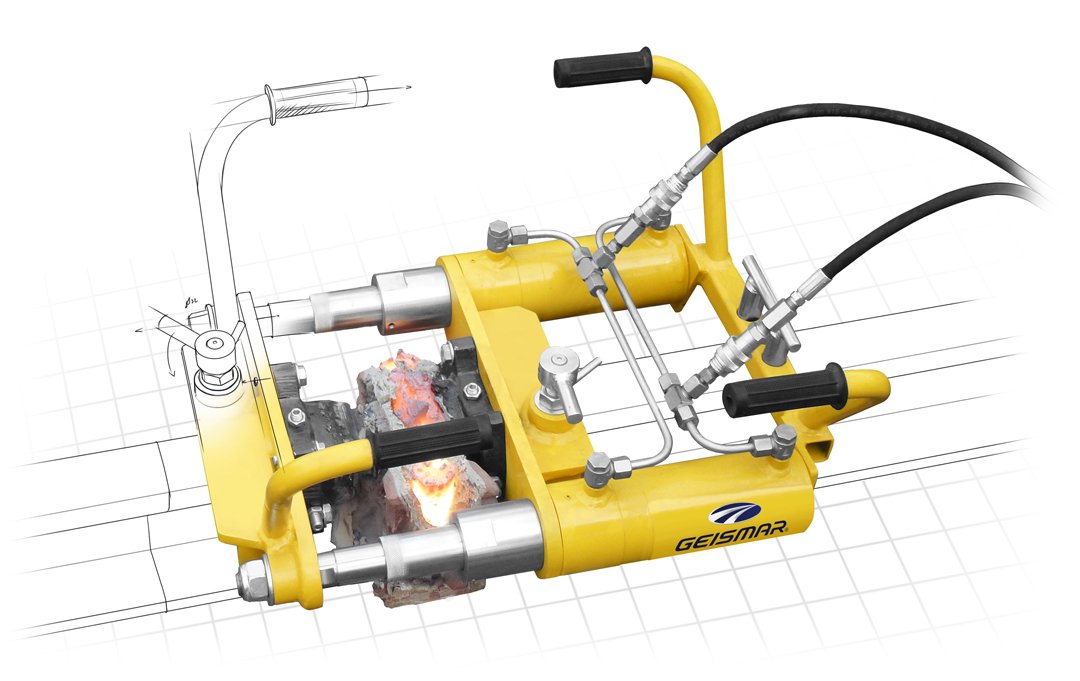

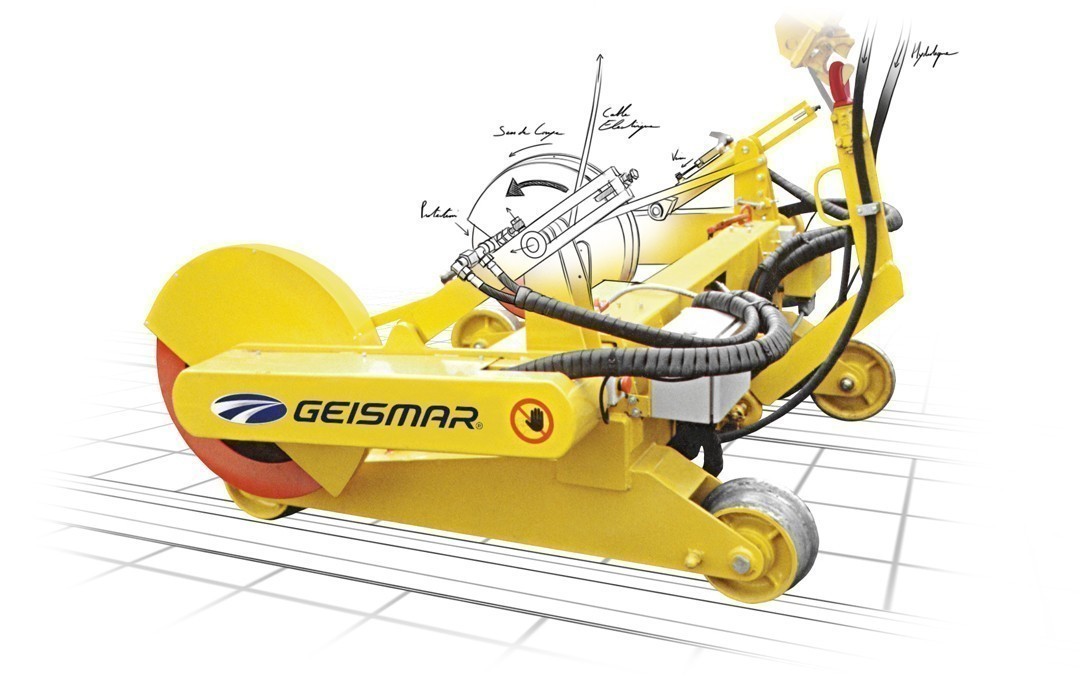

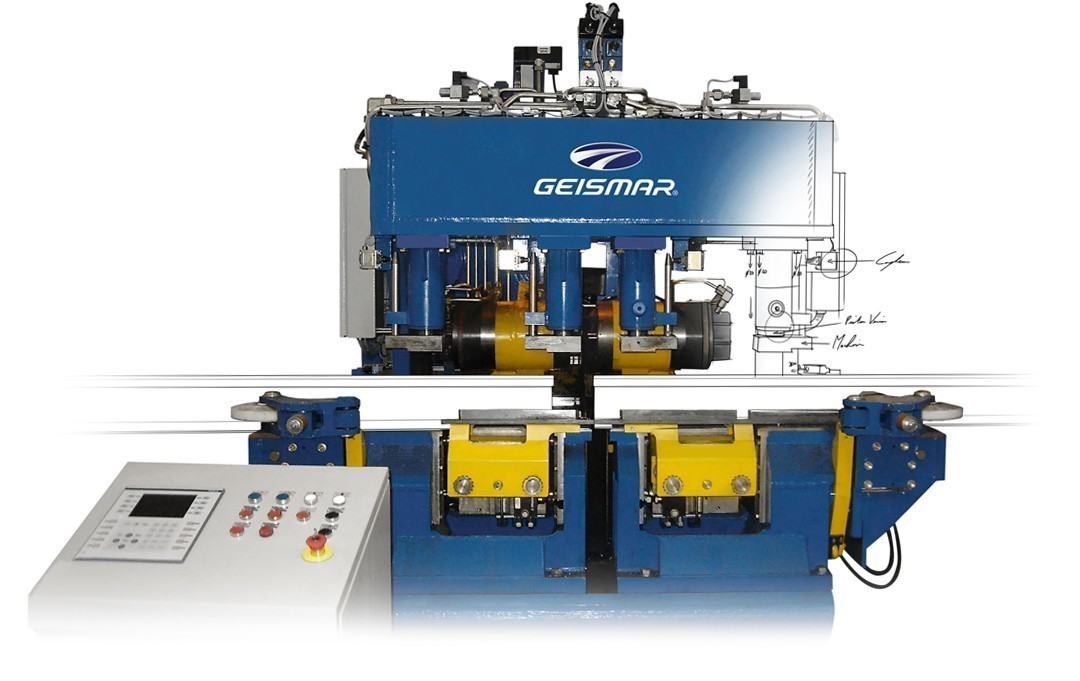

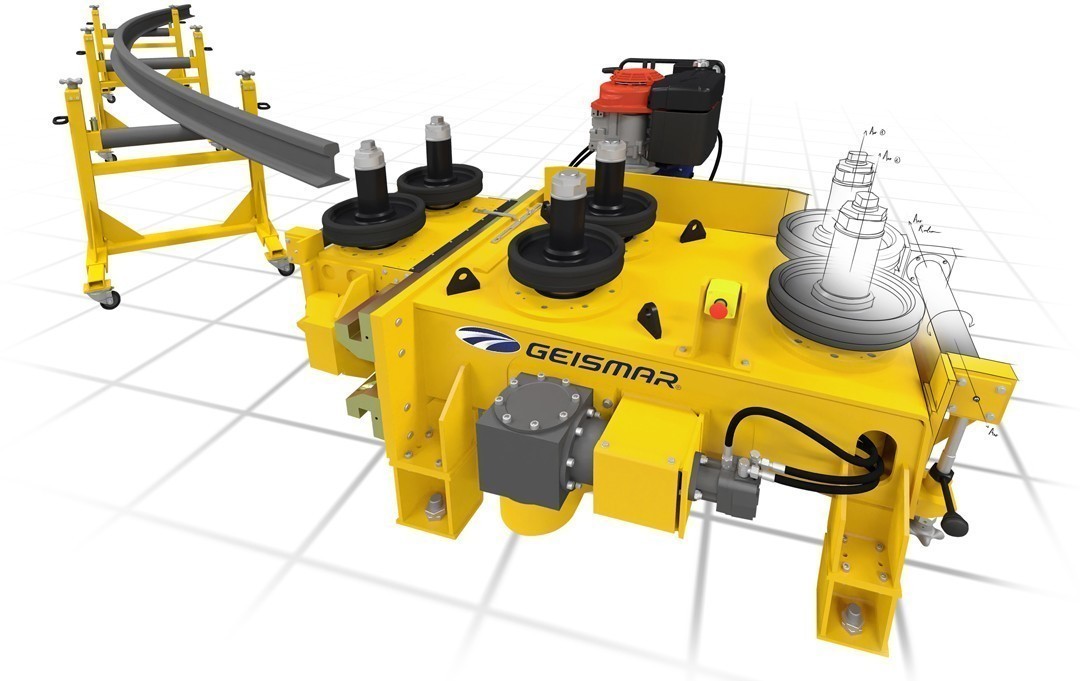

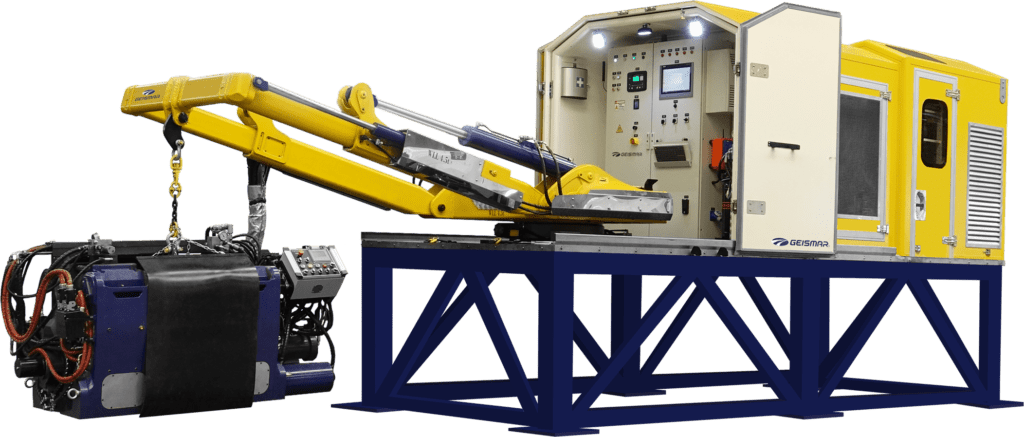

In recent years, advances in rail rolling have led to a dramatic increase in the distance between cuts. As a result, the number of welds required for the construction or renewal of tracks has largely decreased and the use of large fixed welding plants for the production of CWR, such as the Kenitra plant built by Geismar in Morocco for the laying of the Tangier-Kenitra high-speed line in 2015, is no longer as regular as in the past.

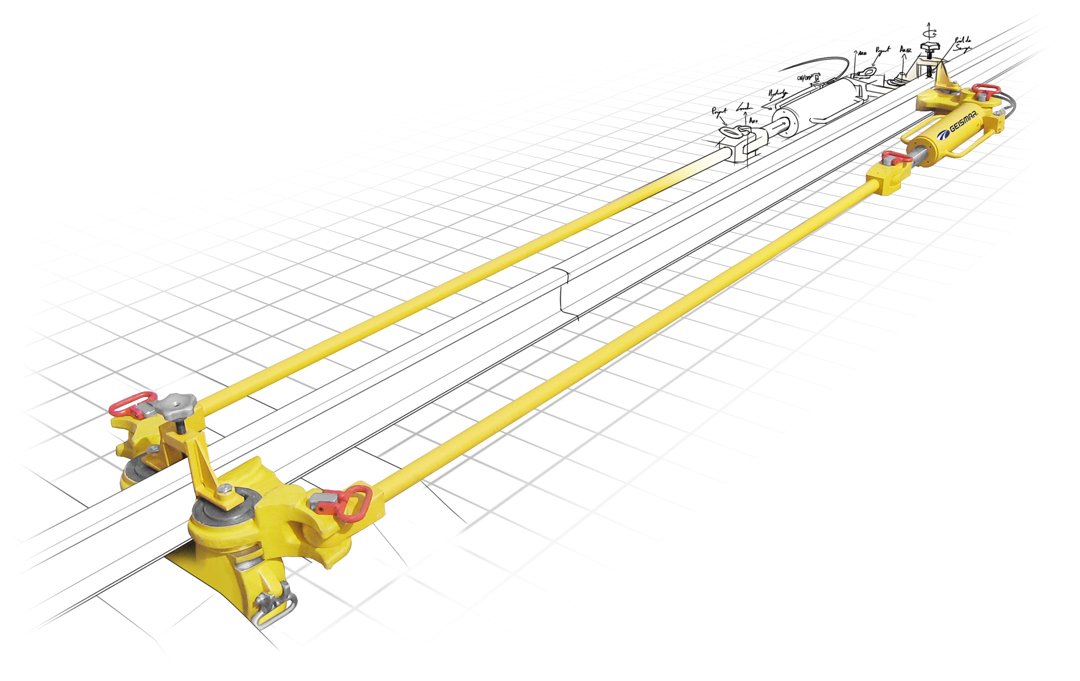

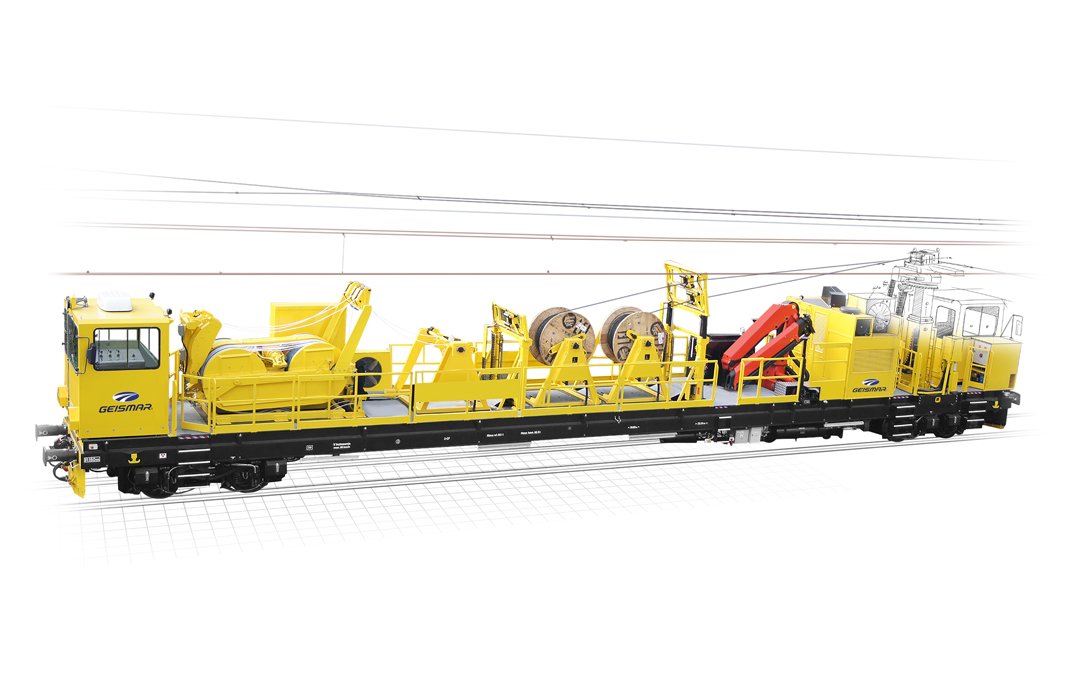

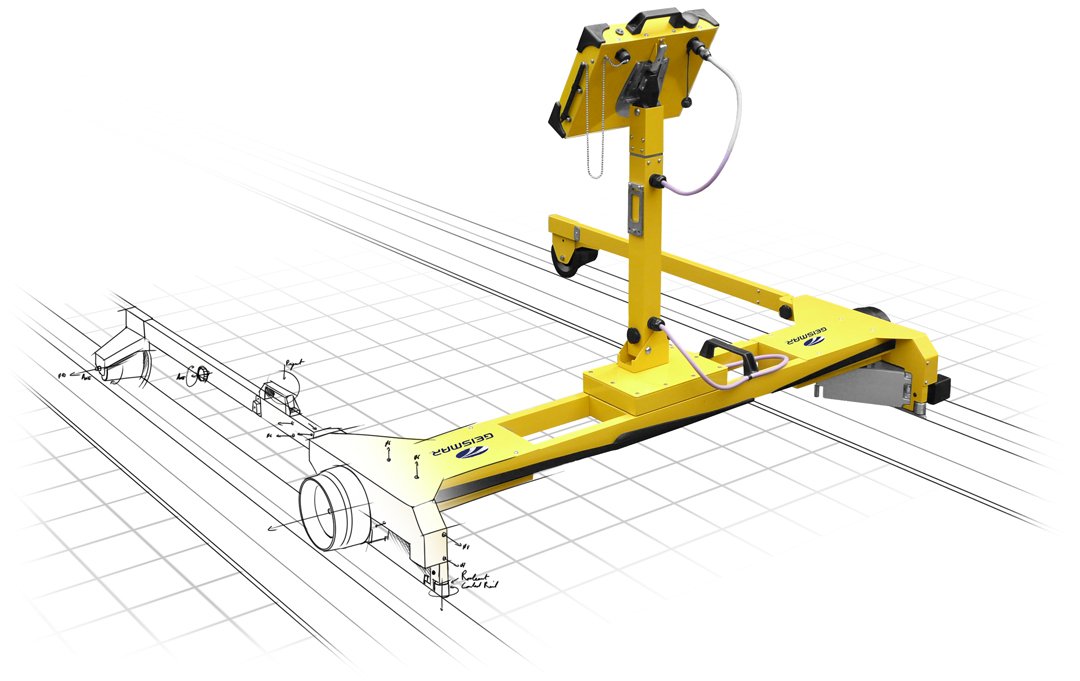

As a consequence of this development, the use of mobile welding units is becoming more and more frequent. The new “Flash” mobile welding head has been developed to meet this need. An example of this new range – the Flash 1000 – will be presented at the IAF in Münster. The Flash 1000 is a mobile welding head for producing high-quality welds using the “Flash Butt Welding” technique and its integrated deburring machine. Easily transportable – using a Geismar Wizard road-rail truck, for example – and self-sufficient for power thanks to the container-generator to which it is connected by a hydraulic arm, the “Flash” welding heads make it possible to carry out high quality in-track welds at a very competitive price compared to the other solutions offered on the market.

Service as a key lever for a more sustainable rail industry:

In addition to supplying machines and construction equipment, Geismar’s mission is to offer its customers solutions that enable them to carry out professional quality work efficiently, economically and safely.

Services – from equipment consulting upstream of projects to equipment refurbishment downstream of jobsites – are an integral part of these solutions. Support solutions throughout the life of machines (maintenance, troubleshooting, retrofitting, etc.) enable equipment owners to improve productivity on the construction site and their overall return on investment.

Geismar offers its customers, among other things, the following:

• Training courses for operators to get to grips with our machines: these training courses help to improve efficiency (acquisition of professional assistance), safety (minimising the risk of errors), operating costs and the lifespan of the equipment,

• Maintenance contracts for up to 5 or 10 years to prevent problems and minimise downtime in the event of an incident (spare parts packs available within 48 hours),

• Extended warranties.

“The speed and quality of our maintenance operations are the two criteria that our customers appreciate most when they call on Geismar’s Services Department. But beyond the particular case of repairs, the services we offer are aimed at improving the productivity of operators and protecting our customers’ investments by extending the lifespan of the machines. These “preventive” services represent a real source of profitability for our customers. Our role is to help them maximise their investment”.

Xavier BOBIN, Director of Services, Groupe Geismar.

A team that listens and is eager to exchange with rail professionals:

Located at section F200 of the Münster exhibition, the Geismar stand is looking forward to welcoming all railway professionals to talk about their problems and to imagine the future of our industry together.

Wednesday 1st June will provide an extra opportunity to spend some quality time with our guests during the Geismar Jazz Party proposed from 6 pm to 9 pm.

The most prominent members of the Geismar Board of Management will be present in Münster during the exhibition. Please do not hesitate to contact us to make an appointment to meet them by writing to the following address: media@geismar.com

Log in

Log in