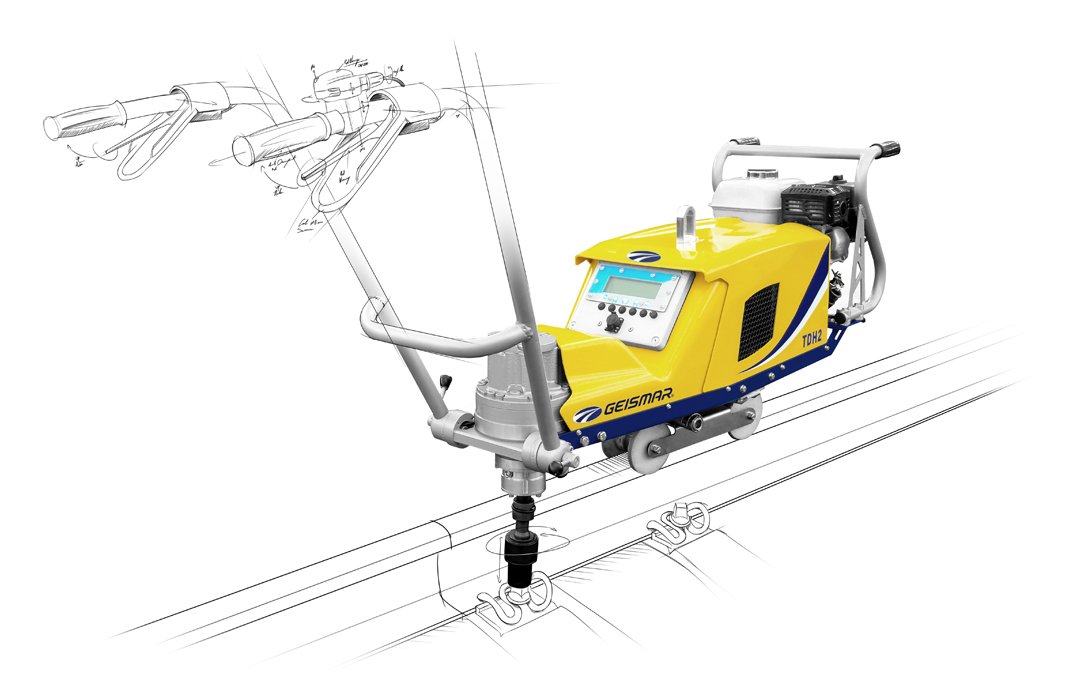

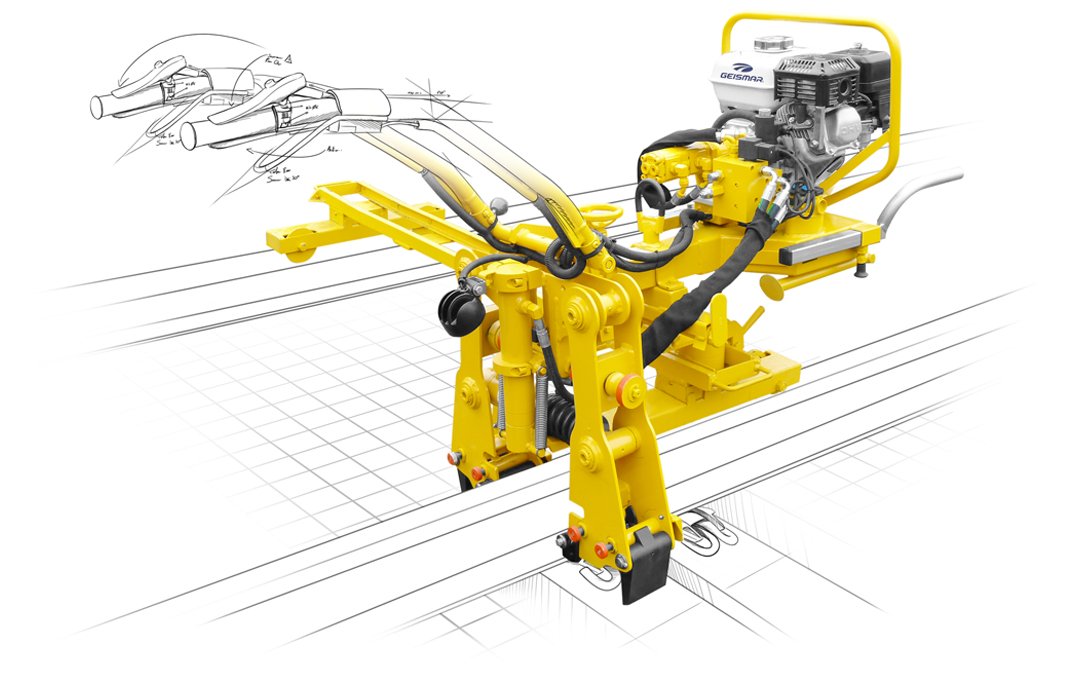

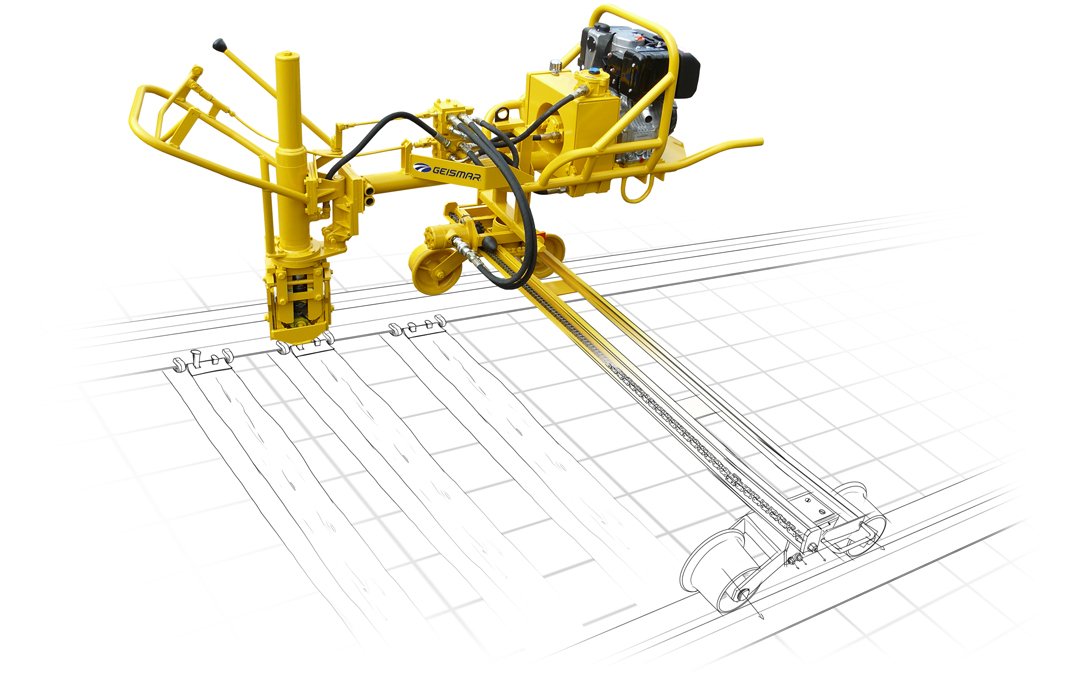

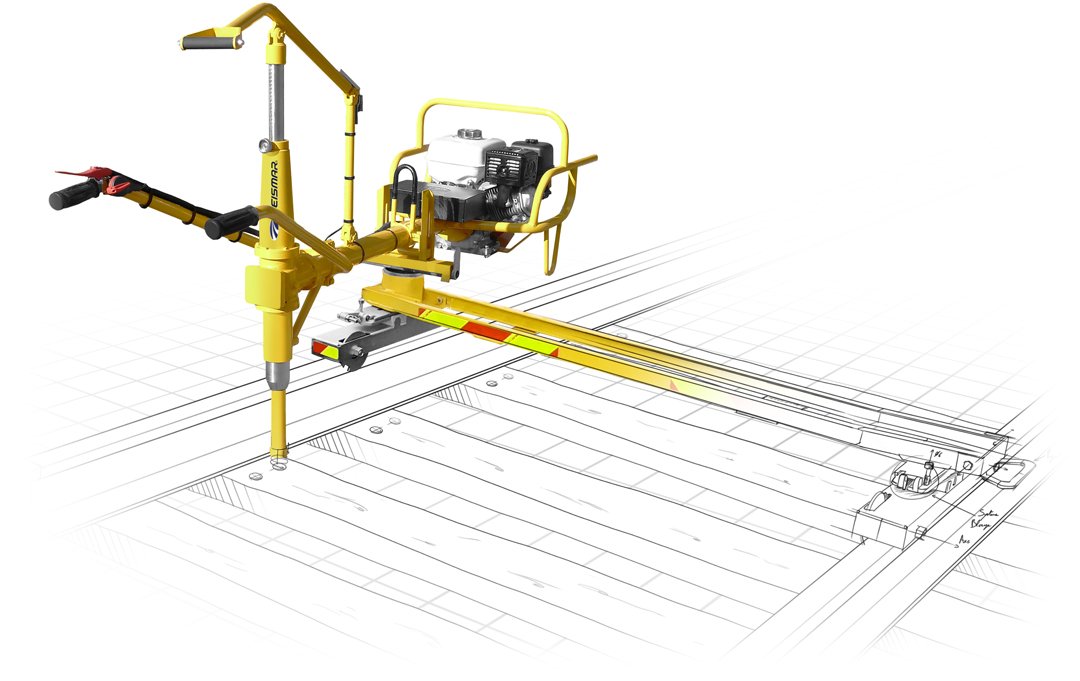

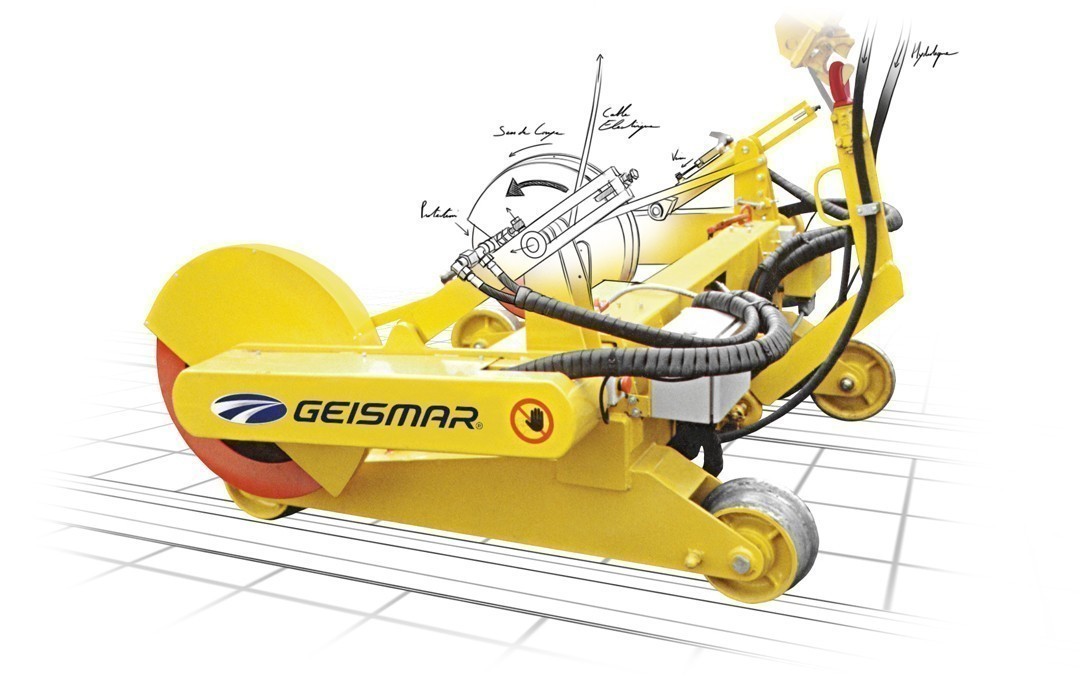

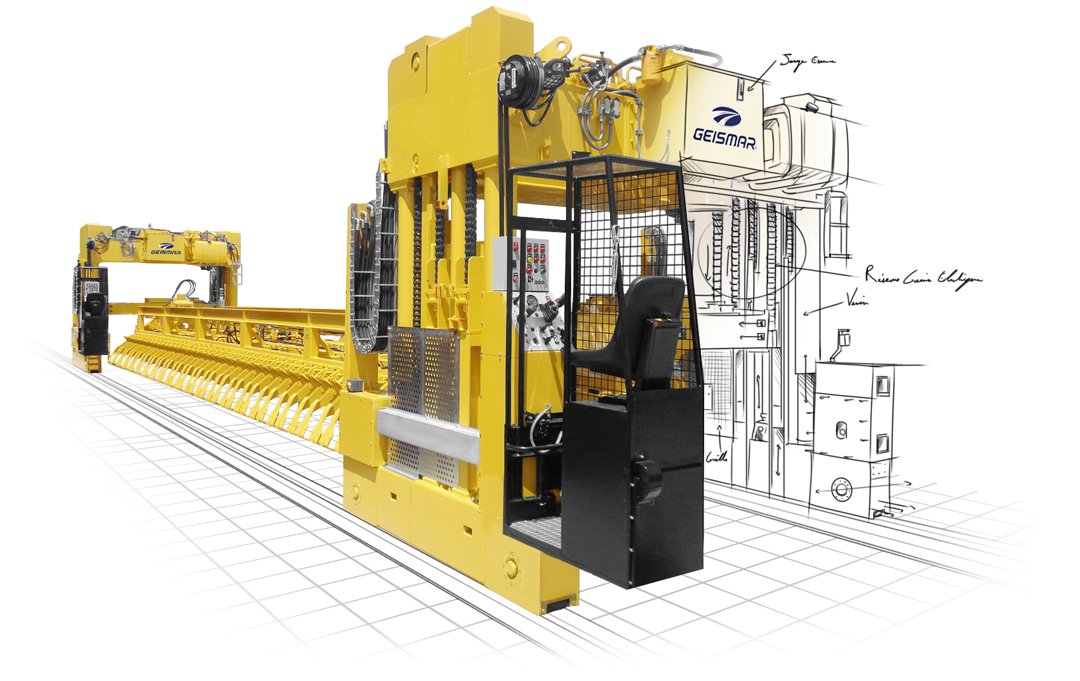

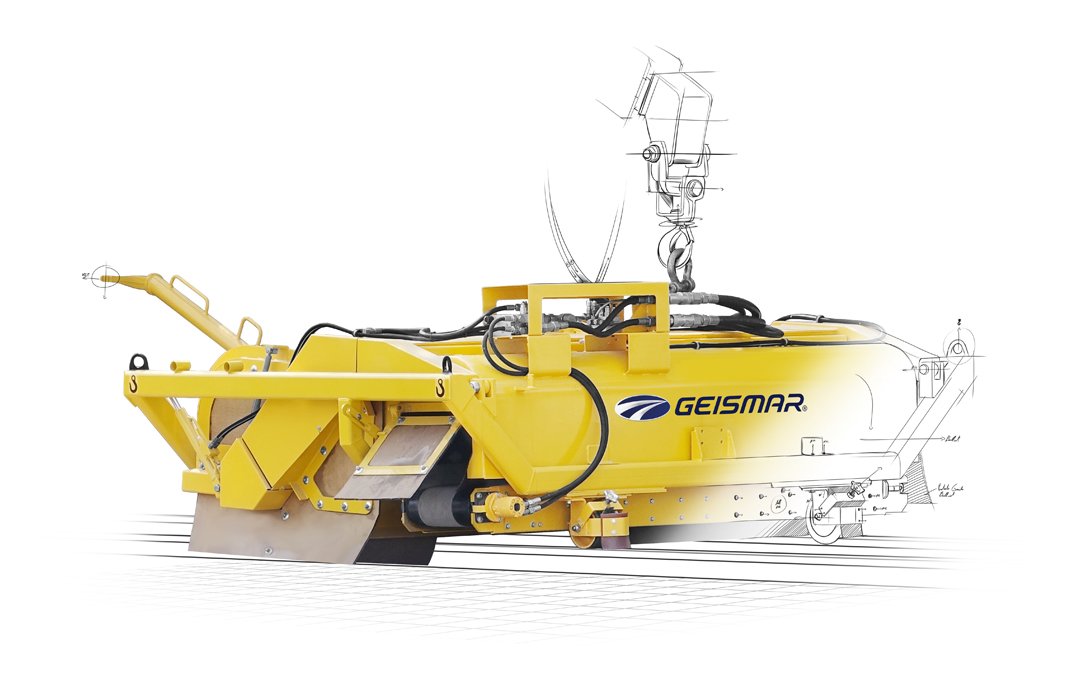

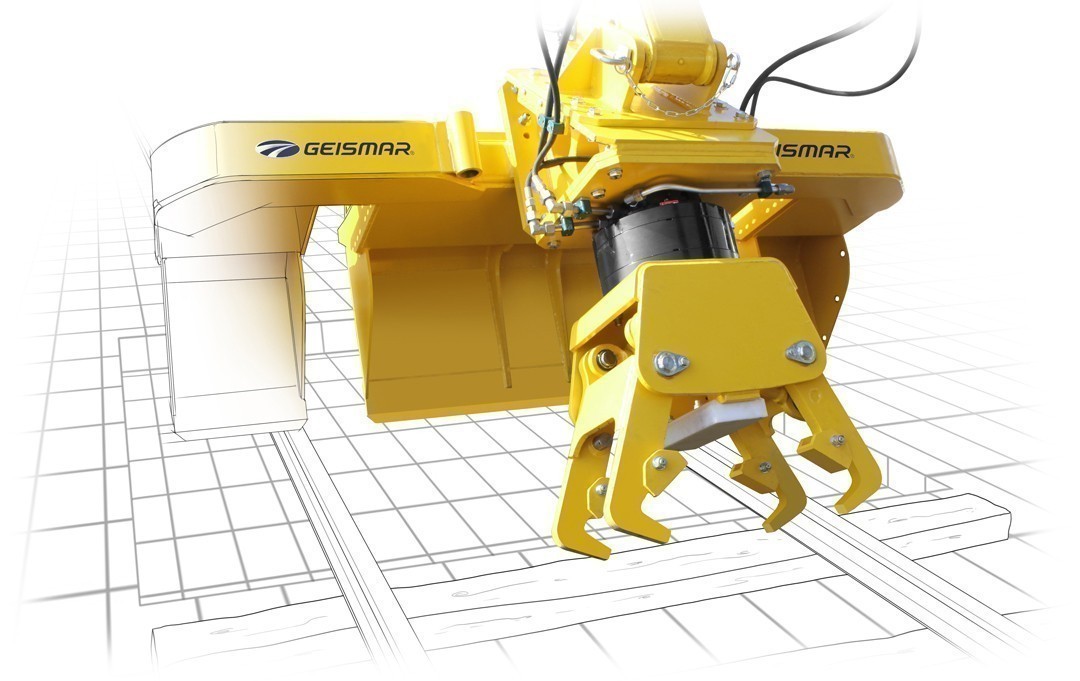

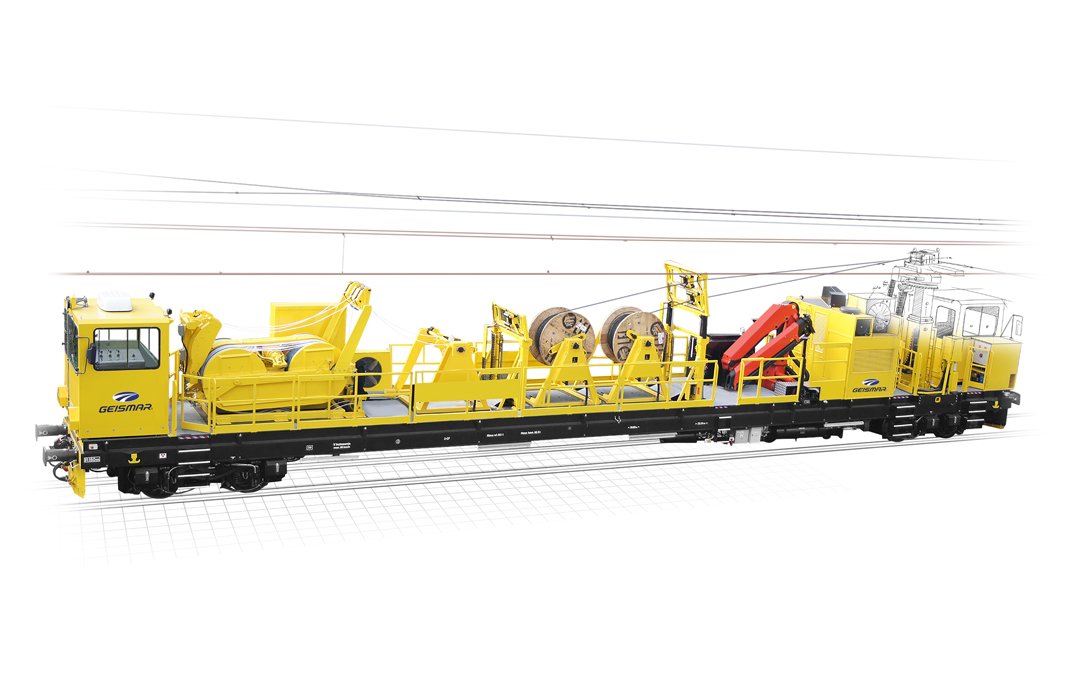

Anticipating the global movement towards solutions that preserve the environment, improve the comfort of workers and minimize negative impact on the neighborhood, Geismar proposes a new global approach towards a sustainable railway world “the sustainable way to rail” which consolidates all its innovative electrically-powered solutions under the name Activion systems.

No Subcategories found! Please choose another category!

Select your region

REGISTRATION PENDING

Thank you for registering to the Geismar Store.

Your request has been submitted to our Customer Service Department for approval. An e-mail notification will be sent shortly to confirm your account activation.

×

UNAUTHORISED ORDER

Only customer business addresses are allowed to order from the Geismar Store.To order by phone, please call +1 847-697-7510

Log in

Log in